China Coiled Tube and Steel Pipe Manufacturers | Quality & Durability

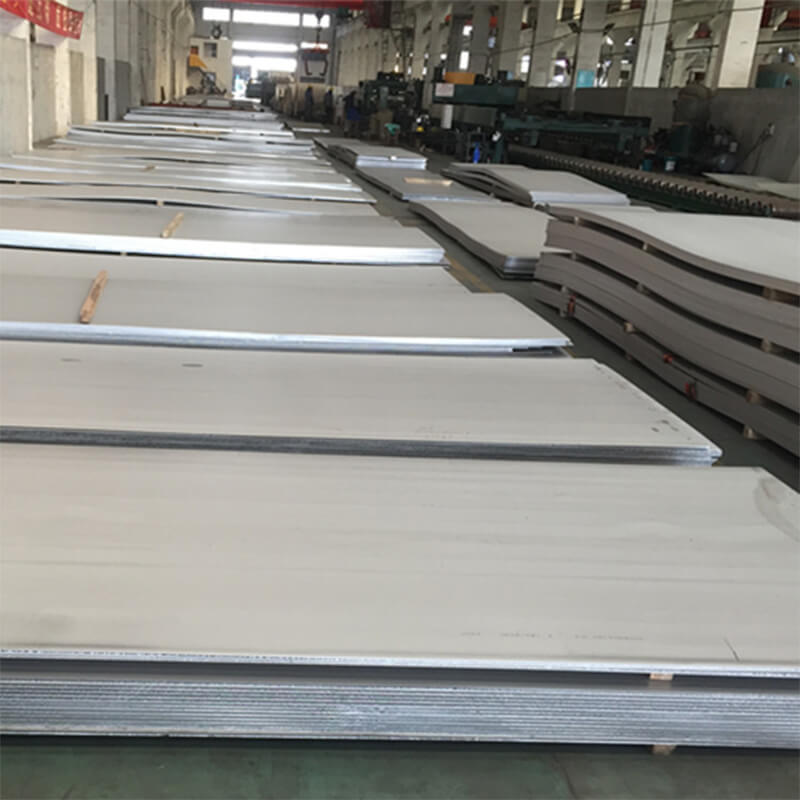

As a buyer in search of high-quality China Coiled Tube and Steel Pipe, I understand the importance of sourcing from reliable manufacturers. These products are essential for various applications, from construction to manufacturing, ensuring durability and efficiency. I appreciate that the coiled tubes are designed to withstand high pressures and extreme conditions, making them ideal for multiple industries. When I look for options, I prioritize manufacturers that offer customization and a variety of sizes to meet my specific needs. Having access to a trusted supply chain is crucial for my projects, and I find that quality and reliability are key factors in my purchasing decisions. With competitive pricing and the ability to cater to bulk orders, I can confidently partner with manufacturers who understand the market demands. When searching for China Coiled Tube and Steel Pipe, I focus on suppliers that can deliver exceptional service and products tailored to my requirements.

China Coiled Tube and Steel Pipe Application From Concept to Delivery

In the realm of modern manufacturing, the demand for high-quality coiled tubes and steel pipes is ever-increasing. These essential components play a pivotal role in various industries, including automotive, construction, and energy. Understanding the journey of these products from concept to delivery is crucial for global procurement professionals seeking reliable partners. The design phase begins with meticulous planning, where engineers collaborate to create innovative solutions tailored to specific applications. This phase is followed by the manufacturing process, which incorporates advanced techniques to ensure precision and durability. Quality control measures are rigorously implemented at each stage, ensuring that the final products meet international standards. Once manufactured, the logistics of delivery come into play. Efficient supply chain management is key to ensuring timely deliveries, as well as meeting customer demands in various global markets. By prioritizing transparency and communication, suppliers can build lasting relationships with buyers, ensuring a seamless transition from production to final usage. As global markets continue to evolve, understanding these processes will empower procurement professionals to make informed decisions and secure high-quality materials essential for their operations.

China Coiled Tube and Steel Pipe Application From Concept to Delivery

| Application Area | Material Type | Diameter Range (mm) | Thickness Range (mm) | Standard Compliance |

|---|---|---|---|---|

| Oil and Gas Industry | Carbon Steel | 20 - 250 | 2 - 10 | API 5L |

| Construction | Stainless Steel | 15 - 150 | 3 - 8 | ASTM A312 |

| Automotive | Alloy Steel | 10 - 100 | 2 - 5 | ISO 9001 |

| Shipbuilding | Mild Steel | 30 - 200 | 5 - 12 | DNV GL |

Related Products