China Heat Exchanger in Furnace & Shell and Tube Heat Exchanger - Manufacturers

When it comes to optimizing heat transfer in industrial applications, the efficiency of a heat exchanger is crucial. My focus is on top-quality China Heat Exchanger specifically designed for furnaces and shell and tube configurations. As a B2B purchaser, you want reliable solutions that meet your operational needs without compromising on performance. I know you might be considering a purchase from various manufacturers, but what sets these heat exchangers apart is their exceptional durability and effectiveness in high-temperature environments. With years of engineering expertise, these units are built to last and improve your process efficiency. When buying, don't just settle for average quality. It's essential to partner with trusted manufacturers who understand the complexities of heat exchange technology and can support your operational requirements. Let me help you find the perfect heat exchanger that aligns with your manufacturing goals and drives productivity forward.

China Heat Exchanger in Furnace and Shell and Tube Heat Exchanger Industry Giant Sets the Industry Standard

In the rapidly evolving landscape of the heat exchanger industry, China has emerged as a formidable player, particularly in the realms of furnace and shell and tube heat exchangers. The country's advanced manufacturing capabilities and innovative technologies have positioned it at the forefront of setting industry standards. As global demand for energy efficiency and sustainable solutions grows, the significance of these heat exchangers becomes increasingly apparent. They play a pivotal role in various applications, including petrochemical, power generation, and HVAC systems, where enhanced thermal performance and reliability are crucial. With a commitment to excellence and a focus on R&D, Chinese manufacturers are continuously improving designs to meet and exceed international standards. The emphasis on high-quality materials, precisely engineered components, and expert craftsmanship ensures that these heat exchangers deliver superior efficiency and longevity. For global procurement specialists, sourcing from leading Chinese manufacturers not only guarantees access to cutting-edge technology but also provides the opportunity to benefit from competitive pricing and diverse product offerings. As the industry shifts towards greater sustainability and innovation, understanding the trends and advancements in China's heat exchanger sector becomes essential. Collaborating with top manufacturers in this region can lead to mutually beneficial partnerships, enabling businesses to optimize their operations while achieving compliance with global standards and regulations. Embracing these developments will ultimately pave the way for enhanced energy utilization and a sustainable future.

China Heat Exchanger in Furnace and Shell and Tube Heat Exchanger Industry Giant Sets the Industry Standard

| Type | Material | Efficiency (%) | Applications | Max Temperature (°C) |

|---|---|---|---|---|

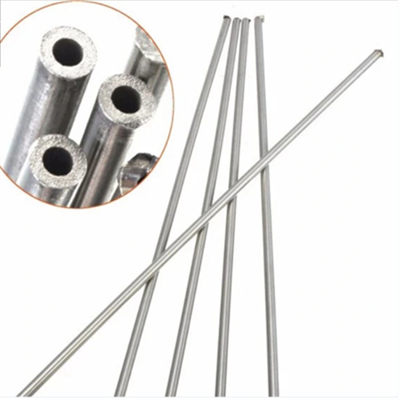

| Furnace Heat Exchanger | Carbon Steel | 90 | Industrial Furnaces | 650 |

| Shell and Tube Heat Exchanger | Stainless Steel | 85 | Chemical Processing | 300 |

| Furnace Heat Exchanger | Alloy Steel | 92 | Oil Refining | 700 |

| Shell and Tube Heat Exchanger | Copper | 88 | Power Generation | 400 |

Related Products