China 316L & 310S Seamless Tube Manufacturer - Quality and Reliability

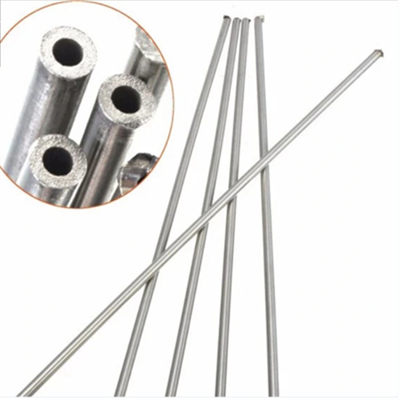

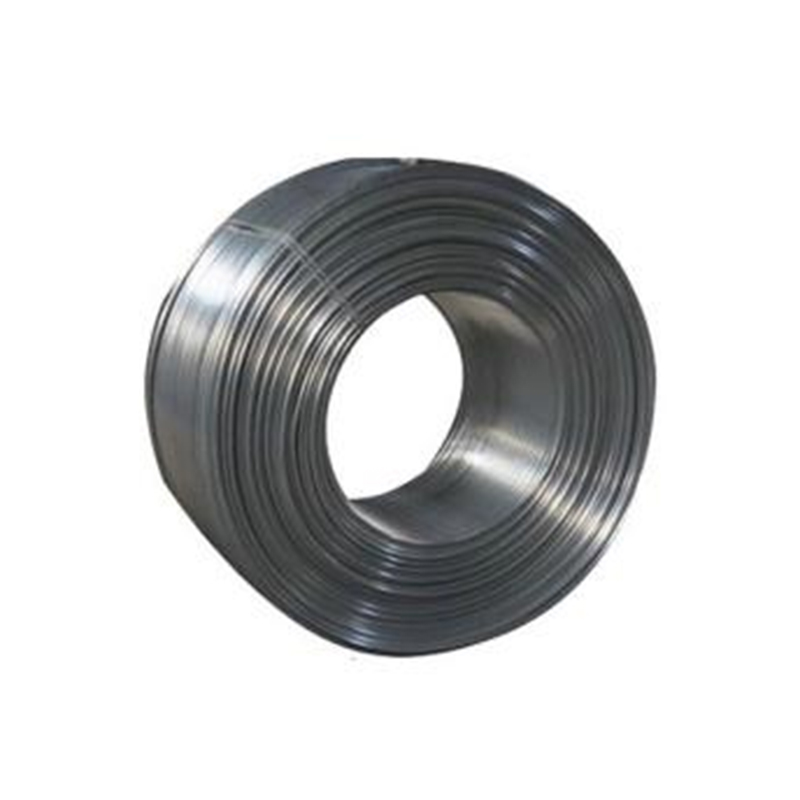

When I think about high-quality stainless steel tubes, I immediately think of the China 316L Seamless Tube and 310S Seamless Tube. These products are not just tubes; they are engineered solutions tailored for various industries, from oil and gas to chemical processing. As a manufacturer in China, I understand the importance of durability and resistance to corrosion that these tubes offer, especially in harsh environments. The 316L variant is perfect for applications requiring high resistance to pitting and crevice corrosion, while the 310S tube excels in extreme temperatures. Each seamless tube is crafted with precision to meet international quality standards, ensuring you get the reliability your projects demand. If you’re in the market for sturdy, dependable seamless tubes, these options are crafted to enhance your operational efficiency. Let’s discuss how we can fulfill your needs and help you succeed in your business endeavors.

China 316L Seamless Tube and 310S Seamless Tube For the Current Year Manufacturers You Can Rely On

In today's competitive global market, sourcing high-quality stainless steel products like 316L and 310S seamless tubes can be challenging. Reliable manufacturers are essential for ensuring that your projects are successful and meet industry standards. For those in search of such products, it's crucial to focus on suppliers known for their quality, consistency, and range of offerings. As the demand for these materials continues to grow, buyers can benefit greatly from partnering with manufacturers who prioritize excellence and adhere to strict production protocols. 316L seamless tubes are renowned for their superior corrosion resistance and strength, making them ideal for various applications, including chemical processing, oil and gas, and food production. Meanwhile, 310S seamless tubes are favored for their high-temperature resistance, making them suitable for furnace applications and heavy-duty components. Ensuring that your supplier has the necessary certifications and a robust quality assurance process is vital to securing the best products for your needs. When selecting a manufacturer for 316L and 310S seamless tubes, look for one that offers a comprehensive range of sizes and finishes to meet specific project requirements. A commitment to innovation and technology can also be a strong indicator of a manufacturer’s reliability, as this often leads to improved product performance and longevity. By partnering with dependable suppliers, businesses can not only achieve compliance with international standards but also foster long-term relationships that drive mutual growth and success.

China 316L Seamless Tube and 310S Seamless Tube For the Current Year Manufacturers You Can Rely On

| Product Type | Material Grade | Diameter Range (mm) | Wall Thickness (mm) | Length (m) | Certificates |

|---|---|---|---|---|---|

| Seamless Tube | 316L | 10 - 100 | 1.0 - 5.0 | 6 - 12 | ISO 9001, ASTM |

| Seamless Tube | 310S | 20 - 150 | 1.5 - 8.0 | 6 - 15 | ISO 9001, ASME |

| Seamless Tube | 316L | 25 - 200 | 2.0 - 6.0 | 10 - 20 | ISO 9001, PED |

| Seamless Tube | 310S | 30 - 250 | 3.0 - 10.0 | 12 - 25 | ISO 9001, TUV |

Related Products