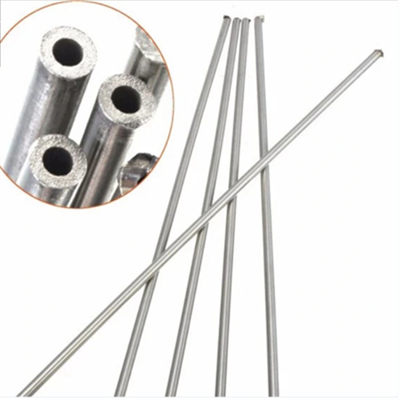

Premium China Copper Nickel Tube Manufacturer for Quality Solutions

As a reliable source for high-quality China Copper Nickel Tube, I understand how crucial it is for businesses like yours to find dependable manufacturers. Our tubes are known for their exceptional corrosion resistance and durability, making them ideal for various applications, from marine environments to industrial projects. With our extensive experience in the industry, I can confidently say that our products meet the highest standards of quality and performance. When you choose us, you’re not just getting products; you’re gaining a partner committed to your success. By collaborating with us, you’ll benefit from competitive pricing, timely delivery, and outstanding customer support. Whether you require standard sizes or custom solutions, we’ve got the capabilities to fulfill your needs. Let’s work together to ensure your projects run smoothly with our trusted Copper Nickel Tube solutions from China!

China Copper Nickel Tube Exceeds Industry Benchmarks Winning in 2025

In recent years, the global demand for copper nickel tubes has surged, driven by their exceptional corrosion resistance, thermal conductivity, and ease of fabrication. As industries strive to enhance their operations, the focus has shifted toward sourcing materials that not only meet but exceed industry benchmarks. A notable player in this field has set its sights on achieving excellence in 2025, positioning itself at the forefront of innovation and quality. This commitment to quality is reflected in the meticulous production processes that encompass state-of-the-art technology and rigorous quality control. By leveraging advanced manufacturing techniques, the company has successfully enhanced the performance of copper nickel tubes, making them ideal for a variety of applications, from marine engineering to oil and gas sectors. Global buyers looking for reliable and high-performance materials will find that these products stand out in terms of durability and reliability, ensuring optimal performance in even the most demanding environments. Looking ahead, the steel industry's focus on sustainability and technological advancement will further drive the evolution of copper nickel tube manufacturing. With initiatives aimed at reducing environmental impact while maintaining high quality, this company is poised to meet the future needs of global procurement. As businesses prepare for a new era of competitiveness and sustainability, choosing a supplier that prioritizes these values will prove essential for success in a rapidly changing market.

China Copper Nickel Tube Exceeds Industry Benchmarks Winning in 2025

| Dimension (mm) | Tensile Strength (MPa) | Elongation (%) | Corrosion Resistance (ASTM B-829) | Thermal Conductivity (W/m·K) |

|---|---|---|---|---|

| 20 x 1.5 | 350 | 50 | Excellent | 400 |

| 25 x 2.0 | 370 | 48 | Very Good | 390 |

| 32 x 2.5 | 320 | 55 | Good | 380 |

| 40 x 3.0 | 340 | 52 | Excellent | 410 |

Related Products