China Finned Tube Manufacturers: Quality Finned Tubes for Your Needs

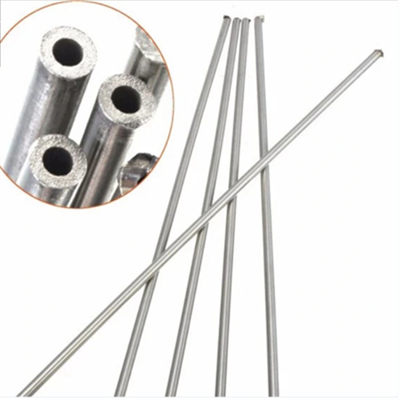

Choosing the right finned tubes for your operations is crucial, and I understand the challenges B2B buyers like you face. Our China finned tube and finned tube solutions are manufactured with precision and care, ensuring top-notch performance. I know you want to maximize heat exchange efficiency while minimizing costs, and that's exactly what our products provide. When you buy from us, you're not just purchasing a product; you're investing in reliability and quality from trusted manufacturers. Our finned tubes are designed to meet diverse applications, making them suitable for various industries. With competitive pricing and excellent durability, you'll find that our products truly stand out in the market. Let’s connect and explore how our finned tubes can boost your operations while fitting your budget perfectly. I’m here to support you in making the best choices for your business needs.

China Finned Tube and Finned Tubne Supplier Pioneers in the Field

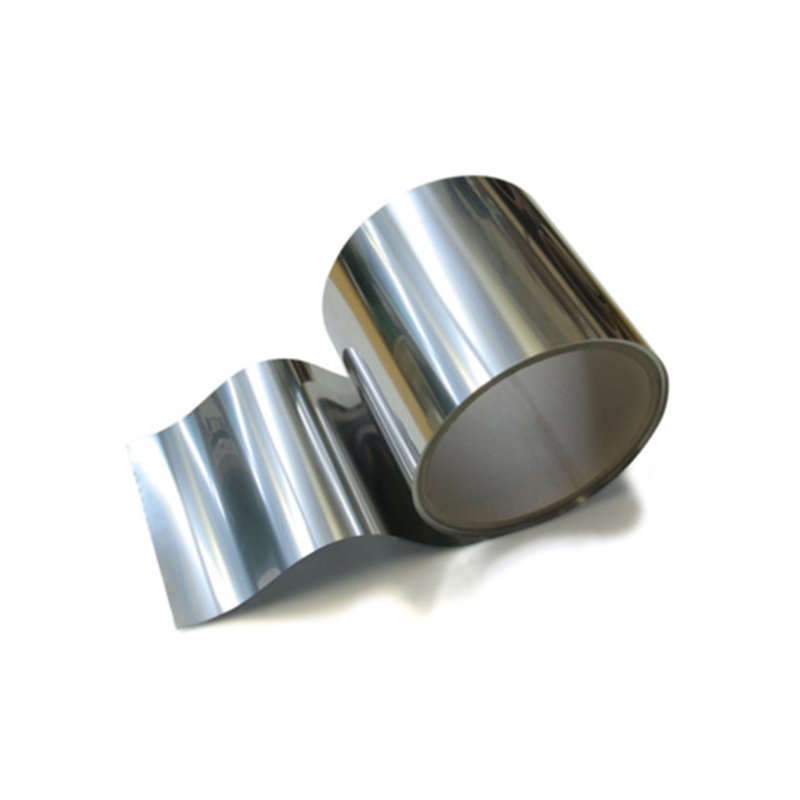

In the fast-evolving industrial landscape, the demand for efficient heat exchangers has never been greater. Finned tubes, recognized for their superior thermal performance, play a crucial role in enhancing heat transfer in various applications, from HVAC systems to petrochemical facilities. As global procurement managers increasingly seek reliable suppliers of high-quality finned tubes, it is essential to identify pioneers who not only understand the intricacies of these products but also lead the industry in innovation and sustainability. One of the key advantages of using finned tubes is their ability to maximize surface area without significantly increasing the volume of material used. This property allows for more efficient heat exchange, making them a cost-effective solution for many large-scale operations. Suppliers in this field are responding to the growing environmental concerns by developing products that not only meet current standards but also incorporate eco-friendly manufacturing practices. This commitment to sustainability, alongside product durability and performance, positions these suppliers as invaluable partners for businesses looking to enhance their operations while maintaining a focus on environmental responsibility. Collaboration and transparency in the supply chain are fundamental trends in today’s market. Forward-thinking suppliers are adopting advanced technologies to provide detailed insights into the production process and material sourcing. By maintaining open lines of communication and offering customizable solutions, these suppliers empower global purchasers to align their specific needs with high-quality products. As the industry continues to innovate, the partnership between suppliers and global buyers will play a pivotal role in driving efficiency and competitiveness in heat exchange applications worldwide.

China Finned Tube and Finned Tube Supplier Pioneers in the Field

| Material Type | Application | Tube Diameter (mm) | Heat Transfer Efficiency (W/m²K) | Corrosion Resistance Rating |

|---|---|---|---|---|

| Carbon Steel | Heat Exchanger | 25 | 600 | Moderate |

| Copper | Air Conditioning | 20 | 700 | High |

| Aluminum | Industrial Heaters | 30 | 650 | Very High |

| Stainless Steel | Power Generation | 40 | 800 | Excellent |

Related Products