China Manufacturer of Heat Exchanger Coil Tubes & Stainless Steel Solutions

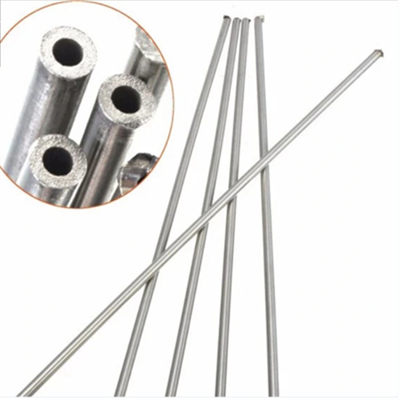

When it comes to high-quality heat exchanger coil tubes, we specialize in China-made options that stand out for their durability and efficiency. My experience in the industry has shown me that our stainless steel heat exchanger coil tubes are manufactured with precision, ensuring optimal performance for various applications. As a buyer, you will appreciate the strength and corrosion resistance of our products, which is critical for demanding environments. I take pride in our commitment to producing reliable and efficient heat exchanger solutions. Each coil tube is crafted with attention to detail, making us a trusted manufacturer in the market. If you’re sourcing from China, I assure you our heat exchanger coil tubes deliver the quality you need while fitting your budget. Let's elevate your operations with superior products that ensure longevity and performance.

China Heat Exchanger Coil Tube and Stainless Steel Heat Exchanger Coil Tube in 2025 Service Backed by Expertise

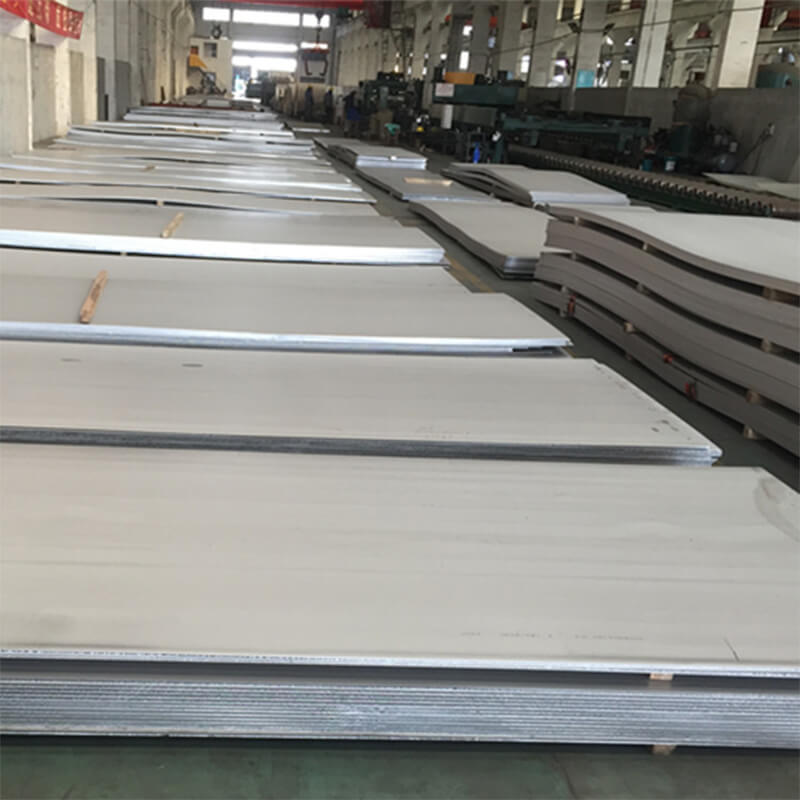

In a world increasingly focused on energy efficiency and sustainability, heat exchangers play a crucial role across various industries. As we look toward 2025, the demand for high-quality heat exchanger coil tubes, particularly in stainless steel, continues to rise. These innovations not only enhance thermal management but also contribute to reducing operational costs. Companies are exploring advanced materials and designs that cater to diverse applications, from HVAC systems to chemical processing. Our extensive expertise in manufacturing heat exchanger coil tubes positions us to meet the evolving needs of global buyers. We emphasize superior quality, durability, and performance. Our stainless steel heat exchanger coil tubes are engineered to withstand high pressures and temperatures, ensuring optimal efficiency and longevity. With rigorous quality control measures and a commitment to innovation, we aim to support industries looking for reliable solutions in their thermal management systems. As we advance into 2025, partnering with a provider that prioritizes both quality and service is essential. Our focus on customer satisfaction means we are prepared to offer tailored solutions that align with specific project requirements. By leveraging our knowledge and capabilities, clients can expect not just products, but a partnership that drives success in their operations, ensuring they stay ahead in a competitive landscape.

China Heat Exchanger Coil Tube and Stainless Steel Heat Exchanger Coil Tube in 2025 Service Backed by Expertise

| Dimension (mm) | Material | Application | Thermal Conductivity (W/m·K) | Corrosion Resistance |

|---|---|---|---|---|

| 15 x 1.0 | Stainless Steel | HVAC Systems | 16.2 | High |

| 20 x 1.5 | Copper | Refrigeration | 385 | Moderate |

| 25 x 2.0 | Titanium | Marine Applications | 22.2 | Very High |

| 30 x 2.5 | Aluminum | Automobile Radiators | 205 | Low |

| 35 x 3.0 | Nickel Alloy | Chemical Processing | 15.5 | High |

Related Products