Top China Steel Sheet Manufacturer - Quality Products for Your Needs

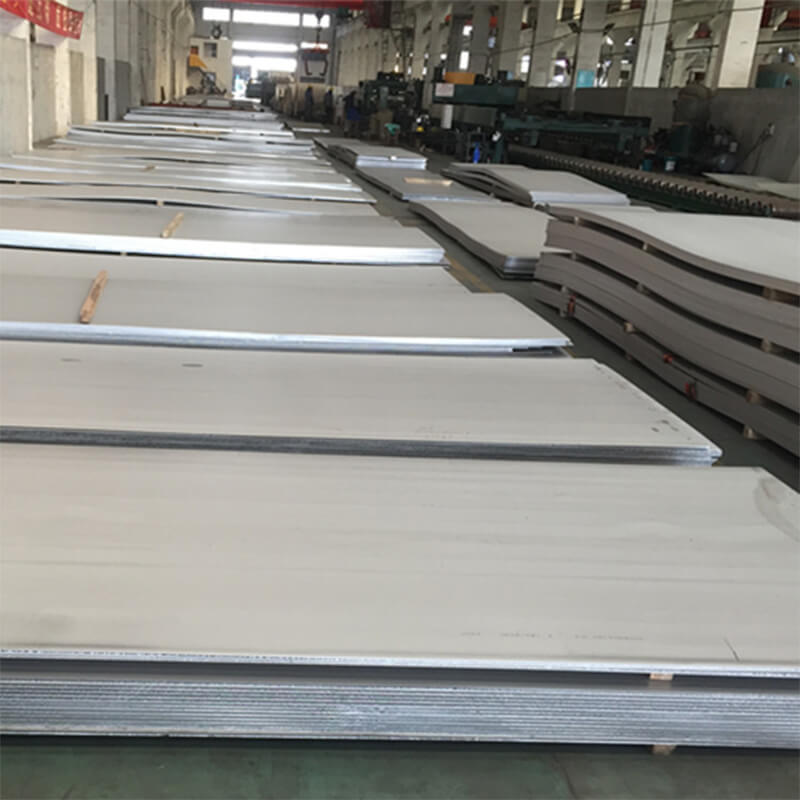

When it comes to sourcing high-quality steel sheets, I find that China steel sheets stand out from the competition. These products are crafted by leading manufacturers that prioritize durability and precision, making them ideal for various industrial applications. I've seen many buyers appreciate the competitive pricing and reliable availability, which is crucial for maintaining production schedules. Each sheet is designed to meet strict quality standards, offering excellent strength-to-weight ratios that can enhance any project. Whether you're looking to manufacture components, create structural supports, or engage in heavy-duty fabrication, the versatility of China steel sheets can meet your needs. By partnering with established Chinese manufacturers, you can ensure a steady supply, helping your business to thrive. The blend of quality and affordability makes these sheets a smart investment for any B2B purchaser.

China Steel Sheet Leads the Global Market Custom Solutions,

In recent years, the demand for high-quality steel sheets has surged across various industries globally. As manufacturers strive to meet the growing requirements for durability, flexibility, and sustainability, the innovation in steel sheet production has become a focal point. One noteworthy contributor to this trend is the customization of steel solutions, which caters to diverse applications ranging from automotive to construction. This shift towards tailored products not only enhances functionality but also provides opportunities for cost savings and efficiency improvements. The global market for steel sheets is becoming increasingly competitive, prompting businesses to seek reliable partners who understand the intricacies of their needs. Custom solutions allow for the adaptation of specifications, thicknesses, and coatings, ensuring that clients receive materials that precisely fit their operational requirements. This flexibility is essential as companies navigate varying standards and performance expectations in different regions, ultimately driving productivity and reducing waste. Moreover, sustainability has emerged as a key consideration, with a growing emphasis on environmentally friendly practices in the metal industry. Modern production technologies aim to minimize carbon footprints while ensuring high-quality outputs. Partners in the steel sheet supply chain who prioritize sustainable practices can contribute to the overall responsibility towards preserving the planet, attracting conscientious buyers. By focusing on these aspects, businesses can secure their foothold in the evolving market, providing customers with exceptional value while meeting their evolving needs.

China Steel Sheet Leads the Global Market Custom Solutions

| Dimension (mm) | Thickness (mm) | Grade | Application | Surface Treatment |

|---|---|---|---|---|

| 1000 x 2000 | 1.0 | SS400 | Construction | Galvanized |

| 1200 x 2400 | 1.5 | S235JR | Automotive | Painted |

| 1500 x 3000 | 2.0 | A36 | Shipbuilding | Hot Rolled |

| 2000 x 4000 | 3.0 | Q235 | Manufacturing | Cold Rolled |

Related Products