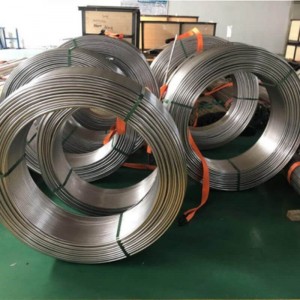

Stainless Steel Coil Tubing

Stainless steel coiled tubing is a very long piece of metal tubing, typically 1 – 3.25 inches in diameter, supplied in large reels in the oil and gas industry. It is used in the arbitration of oil and gas wells, and sometimes as the production tubing of depleted gas wells.

Similar to electrical cables, SS 316 seamless coiled tubing is commonly used to carry out operations. The main advantage over cables is the ability to pump chemicals through coils and be able to push them into holes rather than relying on gravity. Stainless steel coil heat exchangers are suitable for applications such as unit heaters, boiler air preheating, condensation, and cooling as well as high-pressure, air conditioning and dryer applications. Some of the features of coil heat exchangers are flexibility, low-pressure drop, and high efficiency.

304 stainless steel coils are also used for cheaper machining jobs. It is used for hole milling and drilling operations. Coiled tubing steel has a yield strength ranging from 55,000psi -120,000psi, so it can also be used for reservoir fracturing, a process in which fluid is pressurized to thousands of psi at specific points in the well to break up the rock and allow flow Product flow. When used properly, coiled tubing can be used for almost any operation in an oil well operation. ...with Mir test certificate. The advantage of choosing 5/16 Stainless Steel Coil Manufacturers is that the price can be up to 10% less compared to stockists and suppliers in Mumbai and the material is of high quality with factory test certificates.

SS 316 Seamless Coiled Tubing Specification Chart

PVC or TPU coated SS 316 Seamless Coiled Tubing suitable for control lines, umbilicals, and chemical injection lines

| Standard | ASTM A269 /ASME SA 269, ASTM A213/ASME SA213, EN10216-5, JIS G3463 |

| Tolerance | D4/T4 |

| Strength | Tensile, Burst |

| Hardness | Rockwell, Micro |

| Soundness Tests | Eddy Current, Ultrasonic |

| Leak & Strength | Hydrostatic |

| Value Added Services | CuttingBeveling

Threading Polishing (Electro & Commercial) Draw & Expansion as per required Size & Length Destructive and Non Destructive Ultrasonic Testing Annealed & Pickled Bending |

| Available sizes in stock | 1/8“3/16“

1/4“ 5/16“ 3/8“ 1/2“ 5/8“ 7/8“ 3/4“ 1” 1”-1/2“ |

| END | Plain End |

| Types & Their Application | Solar Heater Coil TubeEvaporator Coil Tube

Steam Coil Tube Bear Cooling Coil Tube Cooling Tower Coil Tube Condenser, Boiler Coil Tube |

SS 316 Seamless Coiled Tubing Composition Chart

| Stainless Steel Coil Tube | UNS | C | Mn | P | S | Si | Cr | Ni | Mo | Ti | Nb | N |

| TP304 | S30400 | 0.08 | 2 | 0.045 | 0.03 | 1 | 18.0-20.0 | 8.0-11.0 | ||||

| TP304L | S30403 | 0.035 | 2 | 0.045 | 0.03 | 1 | 18.0-20.0 | 8.0-13.0 | ||||

| TP316 | S3160 | 0.08 | 2 | 0.045 | 0.03 | 1 | 16.0-18.0 | 11.0-14.0 | 2.0-3.0 | |||

| TP316L | S31603 | 0.035 | 2 | 0.045 | 0.03 | 1 | 16.0-18.0 | 10.0-14.0 | 2.0-3.0 |

Mechanical Characteristics of Stainless Steel Coil Tubing

| Material | Heat | Temperure | Tensile Strength | Yield Strength | Elongation %, Min |

| Treatment | Min. | Ksi (MPa), Min. | Ksi (MPa), Min. | ||

| º F(º C) | |||||

| TP304 | Solution | 1900 (1040) | 75(515) | 30(205) | 35 |

| TP304L | Solution | 1900 (1040) | 70(485) | 25(170) | 35 |

| TP316 | Solution | 1900(1040) | 75(515) | 30(205) | 35 |

| TP316L | Solution | 1900(1040) | 70(485) | 25(170) | 35 |