China Tube Straps and Metal Stamping - Leading Manufacturer Solutions

When it comes to reliable China tube straps and metal stamping, I understand the importance of quality and precision in every component. As a dedicated manufacturer, I prioritize durability and performance to meet your specific needs. Our tube straps are designed to provide a secure hold, while our metal stamping services ensure that each part is crafted with attention to detail. I know that sourcing from China can be daunting, but with my extensive experience in the industry, I promise you’ll receive products that exceed your expectations. I focus on using high-grade materials, and I’m committed to delivering on time, every time. Whether you’re looking to streamline your production line or need custom solutions, I'm here to support your business goals. Let's create the perfect fit for your project together. With competitive pricing and a customer-first approach, I can help you thrive in a competitive market. Reach out today to explore how we can work together.

China Tube Straps and Metal Stamping Manufacturers You Can Rely On Global Reach

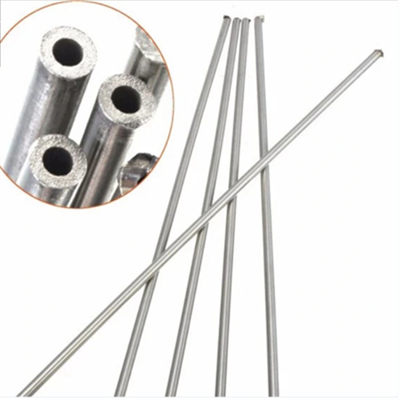

When it comes to sourcing high-quality tube straps and metal stamping products, global buyers need a partner they can trust. China has emerged as a hub for manufacturing these essential components, thanks to its advanced technology and skilled workforce. With a commitment to excellence and precision, manufacturers in this region are equipped to meet diverse needs across various industries, including automotive, construction, and electronics. By choosing a reputable supplier, businesses can ensure that they receive products that not only meet international standards but also offer competitive pricing. The versatility of tube straps and metal stamping makes them vital components in numerous applications. From securing pipes in construction to providing structural support in machinery, these products play a critical role in maintaining safety and efficiency. Manufacturers in China have refined their processes to produce durable, reliable, and innovative solutions tailored to the specific requirements of their clients. In an increasingly interconnected marketplace, leveraging the capabilities of Chinese manufacturers can lead to significant advantages in terms of quality, cost-effectiveness, and timely delivery. Building a global supply chain relationship with a trusted manufacturer is crucial for securing a consistent flow of high-quality materials. By investing in partnerships with Chinese tube strap and metal stamping manufacturers, businesses can enhance their operational efficiency and expand their market reach. With the right manufacturing partner, sourcing these essential components becomes a strategic advantage that empowers companies to thrive in a competitive landscape.

China Tube Straps and Metal Stamping Manufacturers You Can Rely On Global Reach

| Manufacturer Type | Location | Industry Focus | Production Capacity (Units/Month) | Years of Experience |

|---|---|---|---|---|

| Tube Strap Manufacturer | Shenzhen, China | Automotive | 50000 | 15 |

| Metal Stamping Manufacturer | Guangzhou, China | Electronics | 30000 | 10 |

| Tube Strap Manufacturer | Dongguan, China | Construction | 70000 | 20 |

| Metal Stamping Manufacturer | Wuhan, China | Consumer Goods | 25000 | 12 |

| Tube Strap Manufacturer | Ningbo, China | Aerospace | 60000 | 18 |

Related Products