China Finned Tube & High Frequency Welded Helical Fin Tube Manufacturers

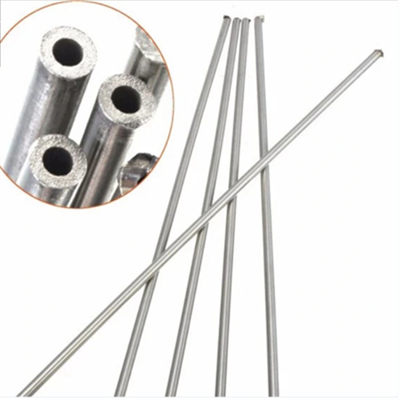

When it comes to high-performance heat exchangers, I highly recommend considering China finned tubes and high frequency welded helical fin tubes. These products are engineered for optimal thermal efficiency and durability, making them perfect for a wide range of industrial applications. As someone who values quality and reliability, I know that sourcing from reputable manufacturers is crucial. I appreciate that these tubes are crafted with precision and meet strict international standards. If you're looking to buy finned tubes that offer exceptional thermal conductivity and resistance to corrosion, you will find a variety of options to suit your needs. The versatility of these tubes allows for customizations to fit specific project requirements, ensuring you get the best performance. Partnering with trusted manufacturers can lead to significant long-term savings and enhanced operational efficiency. Don’t miss out on improving your systems with our high-quality finned tubes!

China Finned Tube and High Frequency Welded Helical Fin Tube Leads the Global Market Outperforms the Competition

The global market for finned tubes has witnessed remarkable growth, with China emerging as a leading supplier of high-frequency welded helical fin tubes. This innovative design offers superior heat transfer efficiency and is vital for various industries, including HVAC, petrochemical, and power generation. The unique welding technology utilized in these tubes enhances their durability and performance, setting them apart from traditional options. One of the key advantages of Chinese finned tubes is their ability to outperform the competition in terms of both cost-effectiveness and quality. Manufacturers leverage advanced production techniques and stringent quality control measures, ensuring that each tube meets international standards. As industries worldwide seek reliable and efficient thermal systems, the demand for these high-performance tubes continues to rise. For global buyers, partnering with leading Chinese manufacturers not only means access to cutting-edge technology but also the assurance of competitive pricing. With a focus on innovation and customer satisfaction, the future of finned tube manufacturing in China looks promising, driving the growth of businesses that rely on efficient thermal solutions. Securing a reliable source of helical fin tubes can significantly enhance operational efficiency, paving the way for lasting success in various industrial applications.

China Finned Tube and High Frequency Welded Helical Fin Tube Leads the Global Market Outperforms the Competition

| Dimension | Material | Application | Market Share (%) | Region |

|---|---|---|---|---|

| 20 x 1.5 mm | Stainless Steel | Heat Exchanger | 25% | Asia Pacific |

| 25 x 2.0 mm | Copper | Cooling Systems | 20% | North America |

| 30 x 1.5 mm | Carbon Steel | Power Generation | 15% | Europe |

| 35 x 2.5 mm | Alloy Steel | Chemical Processing | 18% | Middle East |

| 40 x 3.0 mm | Titanium | Marine Applications | 22% | South America |

Related Products