China Heat Exchanger Tube & Stainless Steel Tube Manufacturers Guide

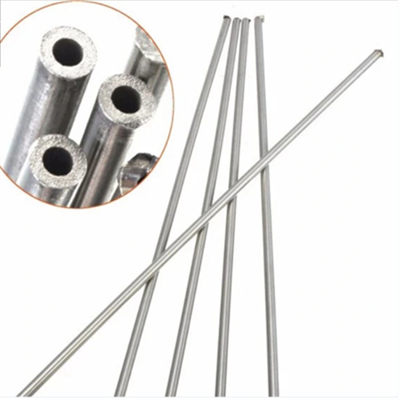

Are you in need of high-quality heat exchanger tubes? We offer premium China Heat Exchanger Tube and Stainless Steel Tube for Heat Exchanger that are designed to meet industry standards and ensure optimal performance. Our products are manufactured with precision and durability in mind, making them perfect for various applications. I understand how crucial it is to find the right supplier. That’s why I’m committed to providing exceptional service and support throughout your purchasing journey. Whether you’re looking to buy in bulk or need assistance with specifications, our team is here to help you every step of the way. With our focus on quality and reliability, you can trust that our tubes will deliver the efficiency you need. Partner with us to get the best solutions for your heat exchanger needs—because finding the right manufacturer matters in your business success. Let’s connect and discuss how we can support your requirements today!

China Heat Exchanger Tube and Stainless Steel Tube for Heat Exchanger Service Pioneers in the Field

In the ever-evolving landscape of heat exchangers, the demand for high-quality heat exchanger tubes and stainless steel tubes is at an all-time high. Companies around the globe are seeking reliable solutions to optimize their thermal systems, improve efficiency, and ensure longevity in performance. Stainless steel tubes, known for their corrosion resistance and durability, are particularly sought after in various industries, including chemical processing, pharmaceuticals, and food and beverage production. Investing in top-notch materials is crucial for organizations aiming to maintain operational reliability and achieve sustained excellence in their applications. The competitive edge in this market hinges on sourcing products that not only meet industry standards but also exceed expectations in terms of quality and performance. By partnering with pioneers in the field of heat exchanger solutions, procurement teams can ensure access to innovative technologies and superior materials. Suppliers dedicated to advancing heat exchange technology play a vital role in providing tubes that support efficient heat transfer while minimizing downtime and maintenance costs. As global businesses continue to pursue sustainability and operational efficiency, the importance of high-performance heat exchanger components cannot be overstated. Companies that prioritize quality while sourcing stainless steel and heat exchanger tubes will find themselves better positioned to tackle challenges and seize opportunities in their industries. Emphasizing reliability, compliance, and innovation in procurement strategies will be essential as companies navigate an increasingly competitive and complex market landscape.

China Heat Exchanger Tube and Stainless Steel Tube for Heat Exchanger Service Pioneers in the Field

| Tube Type | Material | Outer Diameter (mm) | Wall Thickness (mm) | Length (m) | Application |

|---|---|---|---|---|---|

| Heat Exchanger Tube | Stainless Steel 304 | 25 | 2 | 6 | Oil and Gas |

| Stainless Steel Tube | Stainless Steel 316 | 38 | 3 | 12 | Chemical Processing |

| Heat Exchanger Tube | Copper Nickel | 20 | 1.5 | 8 | Marine Applications |

| Stainless Steel Tube | Duplex Steel | 50 | 4 | 10 | Heat Recovery Systems |

Related Products