China Stainless Steel Coil - Trusted Manufacturers for Quality Supply

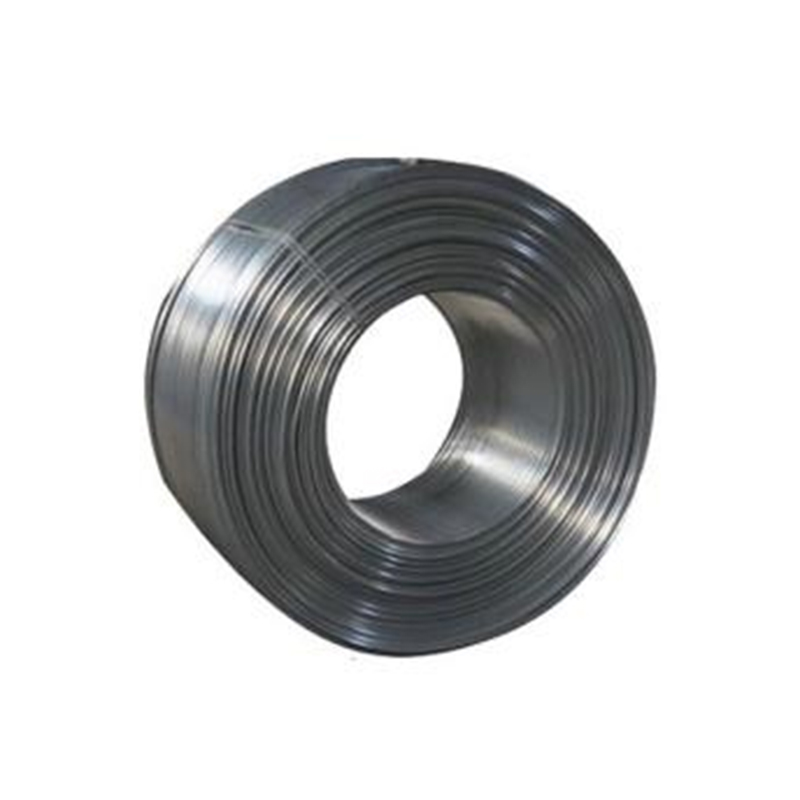

When I think about sourcing high-quality China stainless steel coils, I know how crucial it is to find a reliable manufacturer. The versatility and durability of these coils make them ideal for various applications, from construction to kitchenware. I’ve seen many buyers, just like myself, prioritize strength and corrosion resistance, which is exactly what these products offer. Working directly with reputable manufacturers in China ensures that I get not only competitive pricing but also consistent quality. Whether I’m looking for specific grades or custom sizes, I can rely on these suppliers to meet my business needs. When planning to buy, understanding the specifications and certifications is key, and I've learned that having direct communication with manufacturers simplifies the process. It’s all about building trust and receiving exactly what I need to keep my projects moving smoothly. Let’s connect and explore how these China stainless steel coils can enhance our offerings.

China Stainless Steel Coil Manufacturer Now Trending

As the demand for high-quality stainless steel products continues to rise globally, manufacturers are adapting to meet the needs of diverse markets. The current trend has seen a surge in interest towards stainless steel coils, known for their durability and versatility in various applications ranging from construction to automotive industries. These coils are not only resistant to corrosion but also maintain their strength at high temperatures, making them an ideal choice for modern engineering projects. China has emerged as a key player in the stainless steel coil manufacturing sector, offering a wide range of products that comply with international quality standards. This surge is driven by advancements in production technology and the ability to scale operations efficiently. Global buyers are increasingly looking to Chinese manufacturers for their competitive pricing, extensive product variety, and reliable supply chains. Investing in stainless steel coils from China presents an opportunity for businesses worldwide to enhance their operations with high-performance materials. By choosing reliable manufacturers, buyers can ensure timely deliveries and consistent quality, which are critical factors in maintaining production schedules and meeting customer demands. The trend is not just about sourcing materials; it's about building strategic partnerships that foster growth in the ever-evolving global market.

China Stainless Steel Coil Manufacturer Now Trending

| Grade | Thickness (mm) | Width (mm) | Finish | Production Capacity (tons/month) | Certification |

|---|---|---|---|---|---|

| 304 | 0.5 | 1000 | 2B | 500 | ISO 9001 |

| 316L | 0.8 | 1250 | No.1 | 400 | ASTM |

| 430 | 0.6 | 800 | BA | 600 | SGS |

| 2205 | 2.0 | 1500 | Dull Finish | 300 | CE |

| 301 | 1.0 | 1000 | Mirror Finish | 350 | BIS |

Related Products