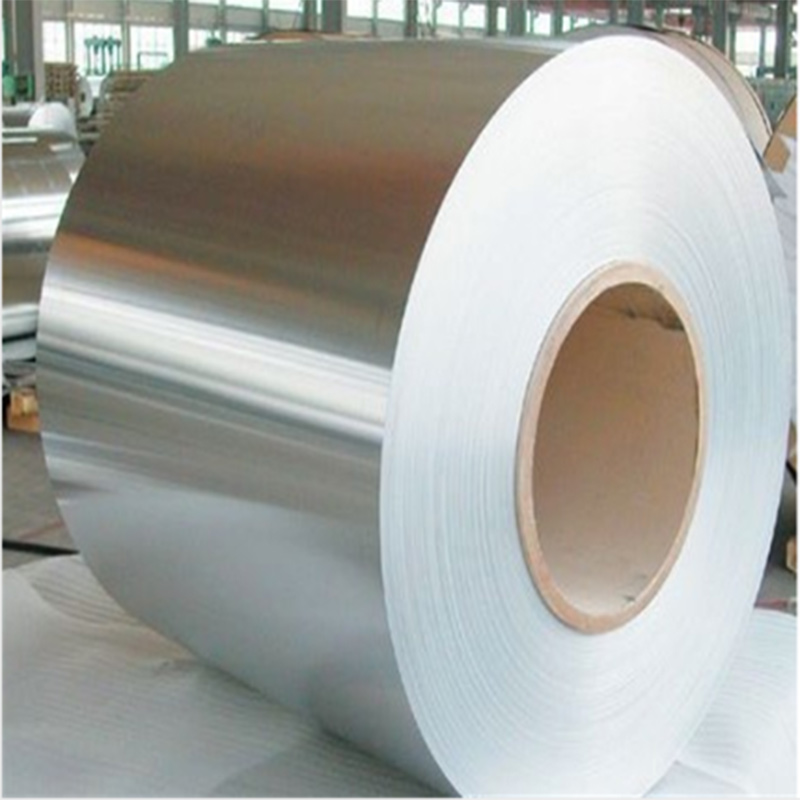

China Stainless Steel Coil Manufacturer: Quality 316 Stainless Steel Coils

As a professional in the stainless steel industry, I understand the importance of high-quality materials for your projects. Our China Stainless Steel Coil and 316 Stainless Steel Coil provide exceptional durability and corrosion resistance, making them ideal for various applications, from construction to automotive manufacturing. I personally ensure that our manufacturing processes meet the highest standards, so you can trust the reliability of our products. When you choose us as your supplier, you're not just getting a product; you're gaining a partner who values quality as much as you do. Whether you are a small business or a large enterprise, our coils can be tailored to fit your specific needs. Let’s talk about how we can support your business with premium stainless steel solutions made in China. Feel free to reach out to get more details on pricing and specifications. Your success starts with the right materials!

China Stainless Steel Coil and 316 Stainless Steel Coil Dominates Market Leader

In the ever-evolving landscape of stainless steel production, China stands out as a dominant player, particularly in the realm of stainless steel coils. The 316 stainless steel coil, known for its exceptional corrosion resistance and high strength, has become a preferred choice for various industries, including marine, chemical processing, and construction. Global buyers are increasingly recognizing the advantages of sourcing these high-quality products from China, where innovative manufacturing techniques and robust supply chains ensure reliability and efficiency. Shandong Zheyi Metal Material Co., Ltd. exemplifies the best practices in the industry, leveraging advanced technology and a commitment to quality control. With rigorous testing standards and a focus on customer satisfaction, companies like Shandong Zheyi meet the diverse needs of international clients looking to enhance their operations with superior materials. The strategic positioning in the heart of China’s manufacturing hub allows for competitive pricing, timely deliveries, and an extensive range of products tailored to specific engineering and design requirements. As global demand for stainless steel coils continues to rise, it is crucial for businesses to partner with manufacturers that not only understand market dynamics but also prioritize sustainable practices. The push towards eco-friendly production processes ensures that sourcing stainless steel coils is not only economically viable but also responsible. By choosing to engage with leading suppliers in China, purchasers can secure a steady supply of high-performance materials that are essential for driving innovation in their respective fields.

China Stainless Steel Coil and 316 Stainless Steel Coil Dominates Market Leader

| Material Type | Market Share (%) | Production Volume (tons) | Application Areas | Growth Rate (%) |

|---|---|---|---|---|

| 304 Stainless Steel Coil | 35 | 500,000 | Construction, Kitchenware | 5 |

| 316 Stainless Steel Coil | 30 | 400,000 | Marine, Chemical Processing | 6 |

| 430 Stainless Steel Coil | 20 | 300,000 | Automotive, Appliances | 4 |

| 2205 Duplex Stainless Steel Coil | 10 | 150,000 | Oil & Gas, Desalination | 8 |

| 201 Stainless Steel Coil | 5 | 100,000 | Consumer Goods, Architecture | 3 |

Related Products