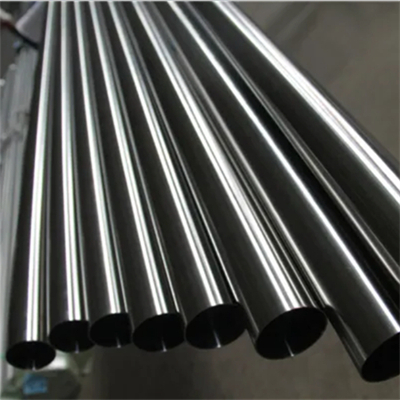

China Manufacturer of Food Grade Stainless Steel & Copper Tube Heat Exchangers

As a manufacturer specializing in high-quality heat exchangers, I’m excited to present our China Stainless Steel Food Grade and Copper Tube Aluminum Fin Heat Exchanger. This product is designed for superior thermal efficiency and reliability in various applications. Crafted with care, our heat exchanger combines robust stainless steel and copper materials to ensure optimal performance while maintaining food safety standards. Whether you’re in food processing, pharmaceuticals, or HVAC, our product guarantees durability and efficiency. With years of expertise in the industry, I understand the importance of dependable equipment for B2B buyers. Our heat exchangers are rigorously tested, offering peace of mind and exceptional value. If you’re seeking a reliable manufacturer in China, look no further. We’re committed to providing outstanding customer service and support, ensuring that your specific needs are met. Let’s collaborate to enhance your operations with our superior heat exchanger solutions.

China Stainless Steel Food Grade and Copper Tube Aluminum Fin Heat Exchanger Industry Giant Guarantees Peak Performance

In the competitive landscape of heat exchanger manufacturing, the importance of high-quality materials cannot be overstated. The use of stainless steel food-grade and copper tubes ensures not only durability but also peak performance, making these products essential for industries requiring stringent sanitation and efficiency standards. As global demand for such solutions continues to rise, manufacturers adept at balancing innovation and quality stand out as industry giants. Sustainable practices and advanced engineering techniques have enabled leading producers to optimize designs that cater to a variety of industrial applications. By harnessing the properties of stainless steel and copper, these heat exchangers offer superior thermal conductivity and resistance to corrosion, leading to enhanced performance and longevity. Additionally, the focus on food-grade materials ensures compliance with international safety standards, making these heat exchangers a reliable choice for food processing, pharmaceuticals, and beyond. As a global procurement partner, choosing the right supplier can significantly impact operational efficiency and product quality. The commitment to excellence in manufacturing processes and customer service becomes a key differentiator. Companies that invest in state-of-the-art technology and skilled workforce create solutions that not only meet but exceed market demands, ensuring that clients receive outstanding value and reliability in their heat management solutions.

China Stainless Steel Food Grade and Copper Tube Aluminum Fin Heat Exchanger Industry Giant Guarantees Peak Performance

| Product Type | Material | Dimensions (mm) | Heat Transfer Efficiency | Applications |

|---|---|---|---|---|

| Plate Heat Exchanger | Stainless Steel | 300 x 400 | 90% | Food Processing, HVAC |

| Shell and Tube Exchanger | Copper Tube | 500 x 200 | 85% | Chemical Processing |

| Finned Tube Heat Exchanger | Aluminum Fin | 600 x 300 | 92% | Refrigeration, Automotive |

| Air Cooled Heat Exchanger | Stainless Steel | 700 x 400 | 88% | Power Generation, Oil & Gas |

Related Products