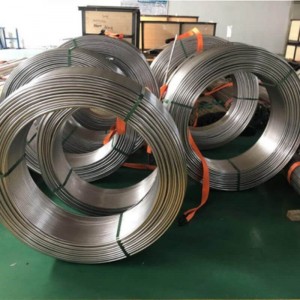

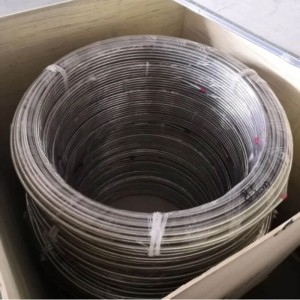

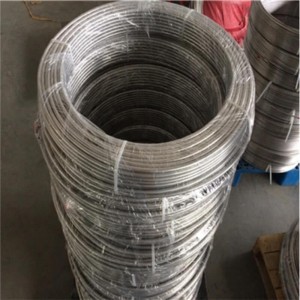

304 coiled tubing Tubing manufacturer welded tubing

Description

We at MBM Tubes are one of the renowned manufacturer, exporter, stockist, stock holder and supplier of a qualitative range of Stainless Steel 304 Coil Tubing that are being designed as per the national and international standard quality of raw materials. SS 304 Coil Tubing has a fuel line which is made from 304 stainless steel coiled tubing. The coiled tubing of SS 304 Seamless Coil Tubing works great for building one piece custom fuel lines without unions. The stainless steel 304 welded tubing is quite double annealed for easy flaring and bending. Also, the tubing of SS 304 Welded Coil Tubing does not include flare nuts.

These Stainless Steel 304 Seamless Coil Tubing products have industry applicability for petrochemical, oil production heat tracing, geothermal and flow measurement applications.

Initially gained a foothold in the market as an economical and efficient wellbore cleanup tool. The economics of intervention and completion operations account for more than 75% of total coiled tubing revenues, and coiled tubing continues to expand in the world's oil and gas fields. In fact, the advantages and application value of coiled tubing (CT), such as underbalanced operation with pressure, fast and efficient operation, low damage to formation, low cost (due to process simplification), were not really recognized until the 1990s, 30 years after the birth of CT. Since then, coiled tubing has been widely used in oil and gas field workover, drilling, completion, logging and other operations, playing an increasingly important role in oil and gas field exploration and development. After the 1990s, coiled tubing fracturing technology and coiled tubing drilling technology have developed rapidly in technological technology and practical application.

Applications include drilling operations, hydraulic fracturing, well completions, removing sand or fill from wellbore, and other applications that involve pumping fluids at high temperatures and high salinity.