Hot Dipped Products from Leading Manufacturers for Quality and Durability

When I think about quality in metal products, Hot Dipped galvanization stands out. I know that it offers exceptional corrosion resistance, making it a top choice for durable applications. If you're in need of reliable supplies, I highly recommend exploring the options available from manufacturers specializing in this process. Whether you’re purchasing for construction, infrastructure, or any other industrial use, knowing you’re getting Hot Dipped products means you’re investing in longevity. I’ve seen how much difference the right materials can make in project success. It’s not just about buying a product; it’s about securing a partnership with a trusted source that understands your needs. Reach out to reputable manufacturers who prioritize quality so you can ensure you're getting the best. This choice can significantly affect your bottom line and project efficiency. Let’s elevate your business together with top-notch Hot Dipped solutions!

Hot Dipped Factory Industry Giant

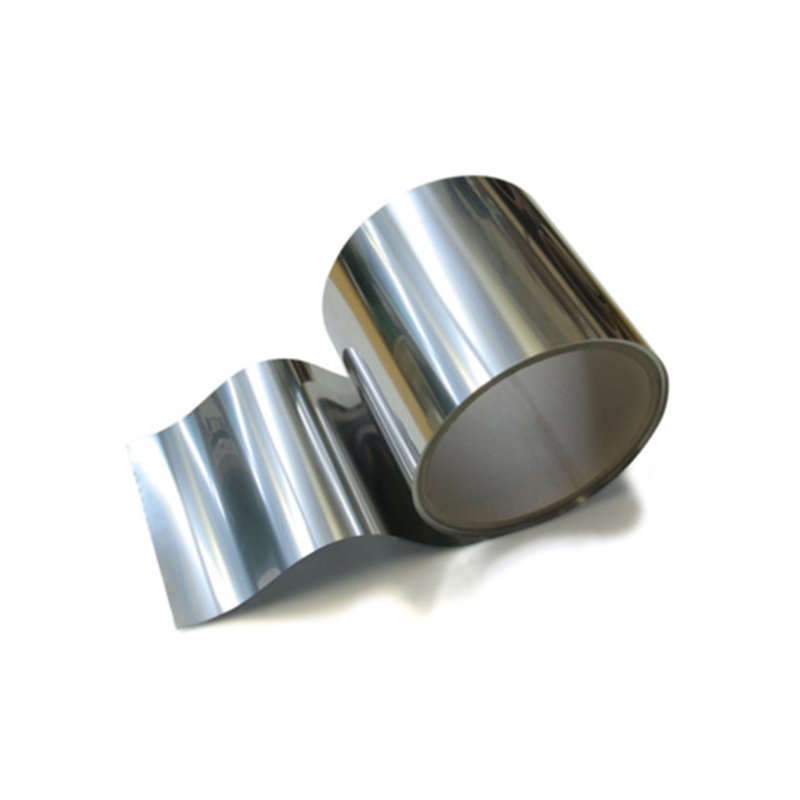

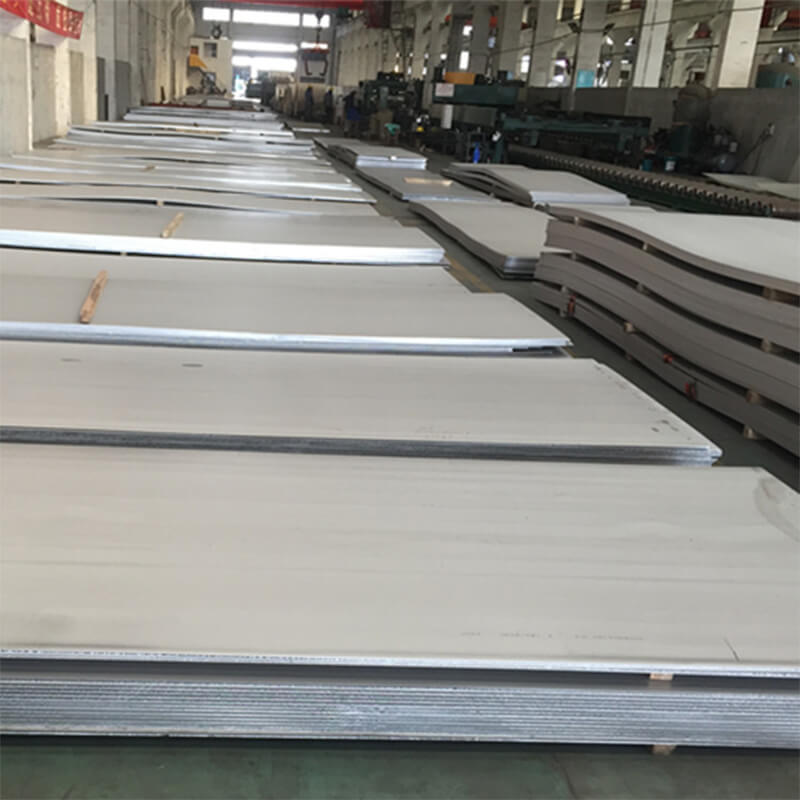

In recent years, the hot-dipped galvanizing industry has witnessed significant advancements, making it an essential choice for numerous applications across various sectors. The robust nature of hot-dipped products ensures superior corrosion resistance, thereby extending the lifespan of materials exposed to harsh environmental conditions. This innovative process involves immersing steel in molten zinc, creating a durable and protective layer. As a result, industries ranging from construction to automotive are increasingly relying on hot-dipped solutions to enhance the performance and resilience of their products. For global buyers seeking high-quality metal materials, understanding the advantages of hot-dipped galvanizing is pivotal. Not only does this technique provide enhanced durability, but it also offers cost-effectiveness over time by reducing maintenance and replacement costs. Furthermore, the consistency in quality and finish achieved through modern manufacturing practices ensures that buyers receive reliable products that meet stringent international standards. As businesses prioritize sustainability and efficiency, the demand for hot-dipped galvanized materials continues to rise, prompting suppliers to innovate and expand their offerings. Investing in hot-dipped galvanizing solutions can significantly impact the efficiency and reliability of your projects. By collaborating with leading manufacturers, businesses can access a diverse range of products tailored to meet specific needs while ensuring compliance with global quality standards. As the industry evolves, staying informed about market trends and technological advancements will be crucial for making well-informed procurement decisions, ultimately contributing to successful and sustainable operations.

Hot Dipped Factory Industry Giant

| Process Type | Material Type | Application | Production Capacity (tons/year) | Quality Standard |

|---|---|---|---|---|

| Hot Dipping | Steel | Construction | 150,000 | ISO 9001 |

| Galvanizing | Aluminum | Automotive | 100,000 | ASTM A123 |

| Pre-Galvanizing | Carbon Steel | Home Appliances | 200,000 | EN ISO 1461 |

| Wire Drawing | Mild Steel | Manufacturing | 80,000 | JIS G 3302 |

| Batch Galvanizing | Stainless Steel | Energy | 120,000 | AASHTO M 111 |

Related Products