Stainless Tube: Top Manufacturers for Quality Products and Services

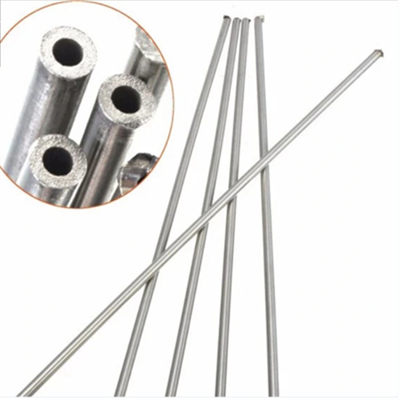

When I think about sourcing high-quality stainless tubes, I get excited about the possibilities they bring to various applications. These tubes are essential for industries ranging from construction to automotive, offering durability and resistance to corrosion. If you’re looking to buy stainless tubes, I suggest focusing on manufacturers known for their commitment to quality and precision. The range of sizes and specifications is vast, so it’s important to identify what meets your unique needs. I’ve found that working directly with trusted manufacturers not only ensures I get exactly what I want but also provides access to competitive pricing. Whether you need them for structural work or specialized industrial projects, stainless tubes are a reliable choice. Let me help you navigate this important decision—ensuring you get the best quality at the right price is what I strive for. Reach out for more details on how we can meet your requirements!

Stainless Tube Dominates From Concept to Delivery

In the world of manufacturing and supply chain management, stainless steel tubes have emerged as a crucial component across various industries. From concept to delivery, the journey of these indispensable materials showcases the commitment to quality, innovation, and efficiency that drives successful global trade. The seamless integration of advanced technology in production processes enables manufacturers to meet the precise specifications required by clients, ensuring that every product not only meets but exceeds expectations. For global buyers, the assurance of reliability is paramount. This is where the ability to trace the production journey holds significant value. From sourcing high-grade raw materials to employing state-of-the-art manufacturing techniques, a transparent and efficient process guarantees timely delivery without compromising quality. Furthermore, the presence of specialized teams working diligently on design and engineering solutions enhances the customization capabilities, allowing for tailored products that cater to specific industry needs. Ultimately, fostering strong partnerships with suppliers who excel in their operational capabilities can streamline procurement strategies. As businesses increasingly seek durable and sustainable solutions, the role of stainless steel tubes continues to expand, presenting opportunities for growth and innovation in diverse applications, from construction to transportation. Embracing this material not only propels efficiency but also positions enterprises as leaders in their respective markets.

Stainless Tube Dominates From Concept to Delivery

| Aspect | Description | Material Type | Applications |

|---|---|---|---|

| Design | Initial concept design for stainless tube structures and components. | 304 Stainless Steel | General piping, kitchen equipment, automotive parts |

| Engineering | Detailed engineering and structural analysis to ensure performance. | 316 Stainless Steel | Marine applications, chemical processing |

| Manufacturing | Production of stainless tubes using advanced techniques. | Duplex Stainless Steel | High-pressure systems, oil and gas |

| Quality Control | Rigorous testing and quality assurance processes. | Nickel Alloy | Aerospace, pharmaceuticals |

| Delivery | Timely and efficient delivery of finished products. | Various Alloy Grades | Construction, architecture |

Related Products