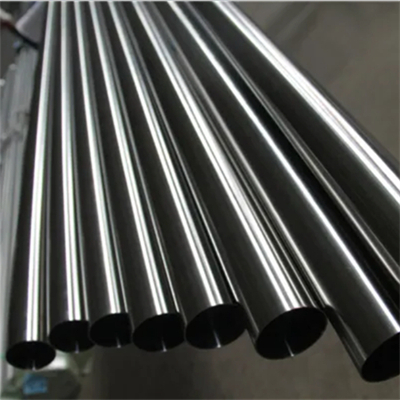

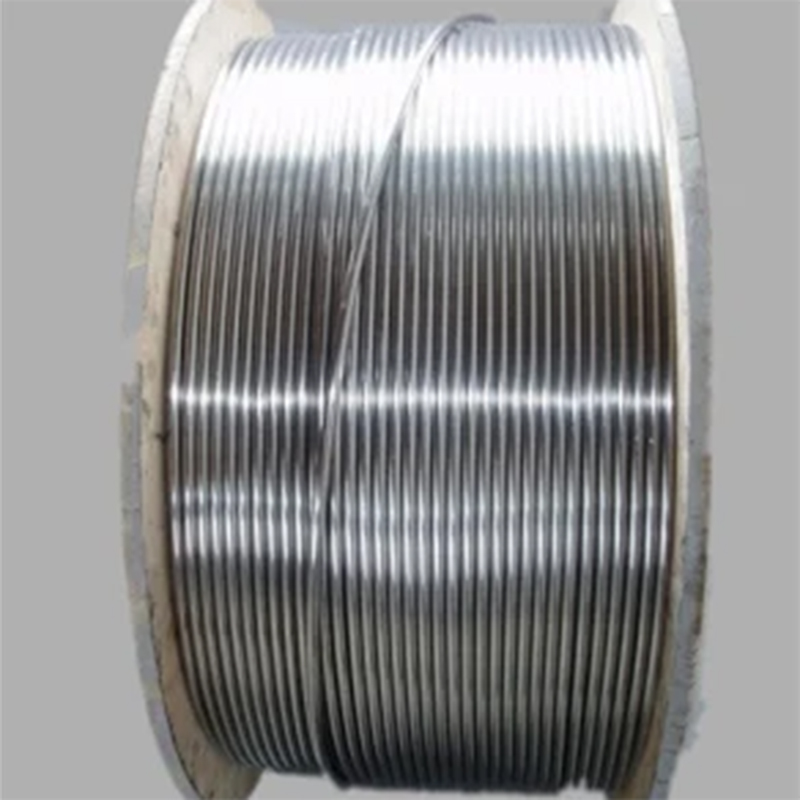

Top China Manufacturer of Quality Steel Pipe Fittings for All Needs

When it comes to sourcing high-quality steel pipe fittings, I've found that partnering with a reliable manufacturer in China makes all the difference. These fittings are essential for ensuring strong and leak-proof connections in various applications, from plumbing to industrial projects. The range includes everything from elbows and tees to reducers and couplings, perfectly catering to diverse needs. As a B2B purchaser, I appreciate the competitive pricing and flexibility offered by Chinese manufacturers. Their advanced production techniques and strict quality control measures guarantee durable products that meet international standards. I can customize my orders to fit specific project requirements, knowing I’m backed by a dependable supply chain. If you’re aiming for efficiency and quality in your projects, consider these steel pipe fittings. Investing in the right manufacturer will ensure you receive not just products, but also peace of mind with your procurement.

Steel Pipe Fittings For the Current Year Sets the Industry Standard

As industries evolve, the demand for high-quality steel pipe fittings continues to rise. In the current year, steel pipe fittings have not only gained momentum in various sectors but have also set a new standard for reliability and performance. From construction to manufacturing, these fittings are essential components that ensure the integrity and efficiency of piping systems. With advancements in material science and production techniques, today's steel pipe fittings are designed to withstand extreme conditions, providing durability and safety for global applications. One key factor driving this standardization is the growing emphasis on sustainability and environmental considerations. Manufacturers are now focusing on creating products that not only meet rigid quality standards but also reduce environmental impact. By utilizing advanced technologies and adhering to international safety regulations, suppliers can offer fittings that meet the diverse needs of clients while ensuring compliance with global standards. As buyers increasingly seek quality, performance, and compliance in their sourcing decisions, it is crucial to partner with suppliers who understand these industry dynamics. The right steel pipe fittings can significantly impact project success and efficiency, making it essential for global purchasers to stay informed about the latest innovations and trends in this ever-evolving market. By prioritizing quality and understanding the importance of compliance, companies can better position themselves to meet the challenges of today's demanding industrial landscape.

Steel Pipe Fittings For the Current Year Sets the Industry Standard

| Fitting Type | Material | Standard | Application | Market Trends |

|---|---|---|---|---|

| Elbow | Carbon Steel | ASTM A234 | Oil & Gas | Growth due to energy demand |

| Reducer | Stainless Steel | ASME B16.9 | Chemical Processing | Increased demand for corrosion resistance |

| Tee | Alloy Steel | ASTM A333 | Power Generation | Focus on efficiency and reliability |

| Cap | PVC | ASTM D2467 | Water Supply | Increasing focus on sustainability |

| Flange | Ductile Iron | API 605 | Construction | Stable demand in industrial sectors |

Related Products