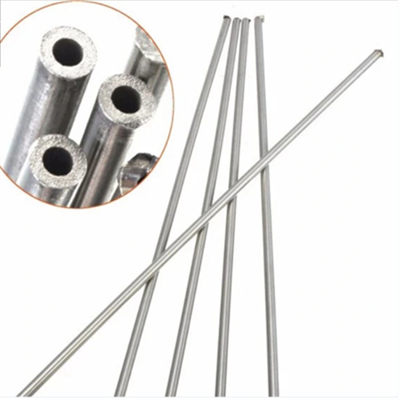

China Manufacturer of Pickling and Polishing Stainless Tubes

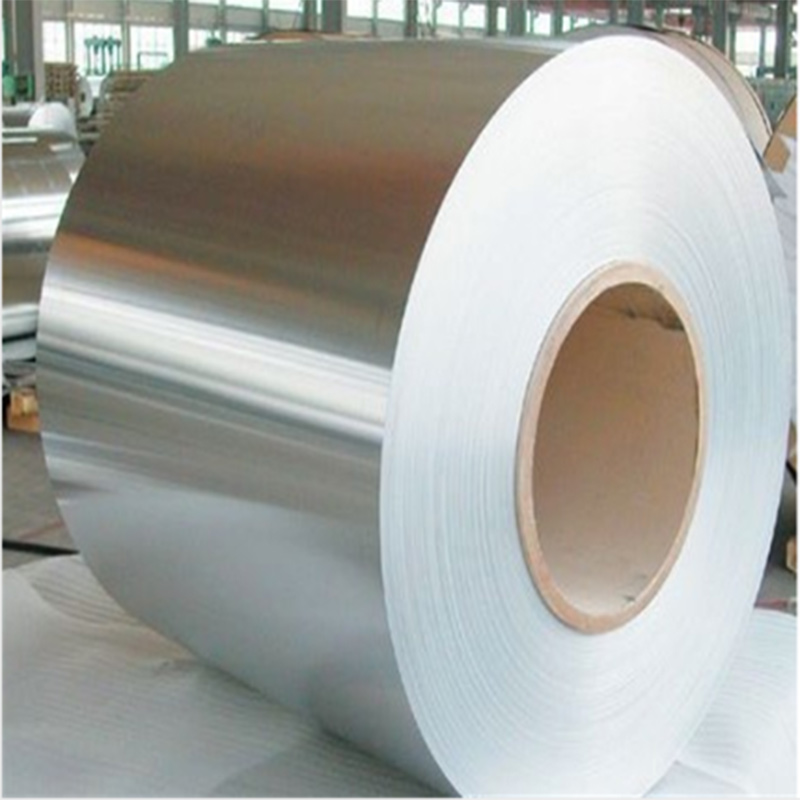

As a trusted manufacturer in the industry, I understand the significance of quality when it comes to China pickling stainless tubes and polishing stainless tubes. Our products are designed to meet the diverse needs of B2B purchasers like you. With a focus on durability and strength, these tubes undergo a stringent pickling process that ensures a smooth finish and resistance to corrosion. I take pride in offering polished stainless tubes that not only comply with international standards but also enhance the aesthetic value of your projects. By sourcing our materials directly from reliable suppliers, we guarantee consistency and reliability in every batch. Whether you’re in construction, automotive, or any other sector needing high-quality stainless tubes, we've got you covered. Partner with us, and let me help you achieve the best results for your applications, making your procurement process seamless and efficient. Quality, affordability, and customer satisfaction are what we promise to all our partners.

China Pickling Stainless Tube and Polishing Stainless Tube in 2025 Now Trending

In recent years, the demand for pickling and polishing stainless tubes has surged in various industries, reflecting a broader trend towards enhanced material properties and aesthetic appeal. As we look towards 2025, this trend is likely to evolve further, driven by advancements in processing technologies and a growing emphasis on sustainability. The pickling process effectively removes impurities and oxidation, resulting in a clean and uniform surface that meets strict industry standards. Coupled with polishing, this process not only enhances corrosion resistance but also significantly improves the visual appeal of stainless tubes, making them highly sought after for applications in architecture, automotive, and various industrial sectors. Global buyers are increasingly seeking suppliers that can provide high-quality pickled and polished stainless tubes. The competitive landscape is pushing manufacturers to innovate and refine their production methods to meet diverse customer requirements. With a focus on quality assurance and adopting eco-friendly practices, suppliers are not only enhancing product performance but also contributing to a more sustainable future. As procurement teams aim to source materials that deliver both functionality and aesthetic value, the relevance of pickling and polishing processes will grow, aligning with the increasing demands for durable and attractive end products. Investing in pickling and polishing stainless tubes will not only cater to immediate needs but also set the foundation for future-proofing supply chains. This strategic move will position businesses to meet consumer preferences for high-quality materials that maintain integrity and appearance over time. As global procurement trends continue to shift, staying ahead of the curve in sourcing such innovative products will be key to achieving long-term success in an increasingly competitive market.

China Pickling Stainless Tube and Polishing Stainless Tube in 2025 Now Trending

| Stainless Tube Type | Size (mm) | Wall Thickness (mm) | Application | Finish |

|---|---|---|---|---|

| Pickling Stainless Tube | 25 | 1.5 | Chemical Industry | Pickled |

| Polishing Stainless Tube | 30 | 2.0 | Food Processing | Polished |

| Pickling Stainless Tube | 40 | 2.5 | Pharmaceuticals | Pickled |

| Polishing Stainless Tube | 50 | 3.0 | Automotive | Polished |

| Pickling Stainless Tube | 60 | 1.8 | Construction | Pickled |

Related Products