Top Seamless Steel Pipe Manufacturers in China – Quality & Reliability

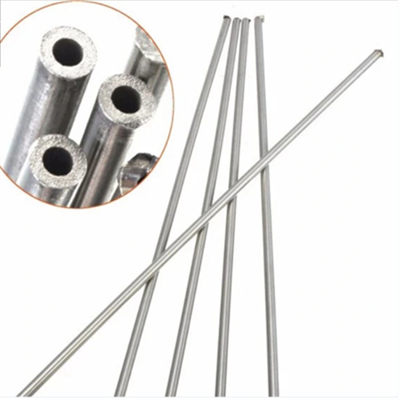

As a buyer in search of reliable seamless steel pipe manufacturers in China, I understand the importance of quality and durability in industrial applications. Our seamless steel pipes are crafted using state-of-the-art technology and meet strict international standards, ensuring that they stand up to the toughest pressures and environments. With a commitment to excellence, our manufacturing processes prioritize precision and efficiency, which translates into products that enhance performance while minimizing costs. Whether I'm sourcing for construction, oil and gas, or automotive industries, I can trust that our seamless steel pipes deliver the strength and reliability needed. Choosing a manufacturer from China means I can access a vast range of sizes and specifications, tailored to my project requirements. Let’s connect and explore how our seamless steel pipe solutions can elevate my business to new heights, ensuring productivity and satisfaction in every application.

Seamless Steel Pipe Manufacturers Application Industry Giant

Seamless steel pipes are essential components in numerous industries, ranging from oil and gas to construction and automotive. The manufacturing process of these pipes involves a combination of modern technology and traditional craftsmanship, ensuring high durability and performance in demanding environments. As global demand for reliable and efficient piping solutions continues to rise, the role of seamless steel pipe manufacturers has become increasingly critical. Their ability to provide customized solutions tailored to specific industry requirements sets them apart in the competitive landscape. One of the powerful applications of seamless steel pipes is in the energy sector, particularly in oil and gas extraction and transportation. These pipes are designed to withstand high pressure and temperature, making them ideal for high-stress environments. Additionally, seamless steel pipes are widely used in the construction industry for structural applications, providing strength and reliability for various projects. Automotive manufacturers also leverage seamless steel pipes for their lightweight yet robust properties, which contribute to fuel efficiency and overall vehicle performance. As a procurement professional, choosing the right seamless steel pipe supplier is crucial. Key factors to consider include product quality, manufacturing standards, and the ability to meet delivery timelines. Manufacturers committed to excellence ensure their products undergo rigorous testing to meet international standards, giving buyers the confidence they need in their supply chain. In a world where quality and efficiency drive success, seamless steel pipe manufacturers play a pivotal role in enabling industries to achieve their operational goals.

Seamless Steel Pipe Manufacturers Application Industry Giant

| Industry | Application | Pipe Diameter (mm) | Material Grade | Operating Temperature (°C) |

|---|---|---|---|---|

| Oil and Gas | Transporting Crude Oil | 100 | API 5L Grade B | 70 |

| Construction | Structural Support | 150 | ASTM A500 | 45 |

| Automotive | Exhaust Systems | 80 | AISI 304 | 200 |

| Chemical Processing | Fluid Transport | 50 | ASTM A69 | 30 |

| Shipbuilding | Hull Construction | 200 | ABS Grade A | 60 |

Related Products