China Manufacturer of Corrosion Resistant Coil Tube & Stainless Steel Coil

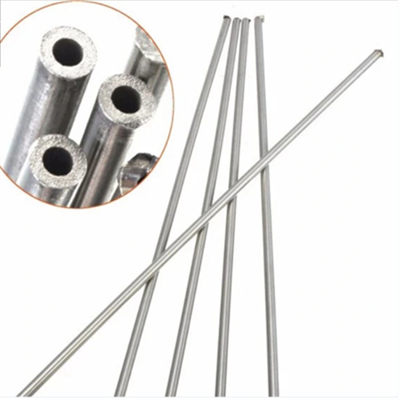

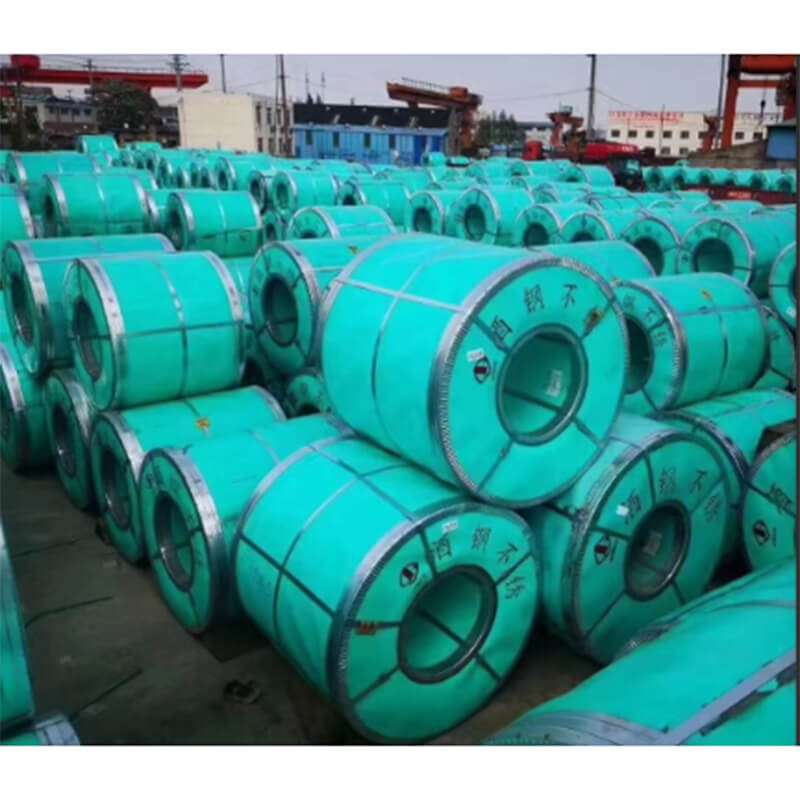

When sourcing corrosion-resistant coil tubes, I highly recommend considering our offerings of China corrosion-resistant coil tube and stainless steel coil tube. As a manufacturer based in China, we specialize in producing high-quality tubes designed to withstand harsh environments, ensuring longevity and durability in your applications. Our coil tubes come in various sizes and specifications, tailored to meet different industrial needs. We focus on precision engineering and use only the best materials, which makes our products ideal for various applications, including HVAC systems, chemical processing, and marine environments. By choosing our stainless steel coil tubes, you’re not just investing in a product, but also in your peace of mind knowing they are built to last. I invite you to explore the advantages of working with a trusted manufacturer who understands your needs and is committed to providing exceptional service and quality. Let’s enhance your operations with our reliable coil tube solutions!

China Corrosion Resistant Coil Tube and Stainless Steel Coil Tube Application Now Trending

In the ever-evolving landscape of industrial materials, the demand for corrosion-resistant coil tubes and stainless steel coil tubes has seen a remarkable surge. As industries increasingly prioritize durability and performance, these materials are gaining traction across various applications, ranging from chemical processing to HVAC systems. Their resistance to corrosion and high-temperature stability makes them ideal for environments that pose significant challenges, including exposure to aggressive chemicals and extreme weather conditions. Furthermore, the versatility of these coil tubes allows for innovative applications in industries such as oil and gas, pharmaceuticals, and food production. Their ability to maintain structural integrity under pressure further enhances their appeal to global buyers seeking reliable solutions for their operational needs. As manufacturers continue to optimize their production processes for these materials, procurement professionals can benefit from a diverse range of options that meet stringent quality standards and regulatory requirements. Overall, the rising trend of utilizing corrosion-resistant and stainless steel coil tubes reflects a broader commitment to enhancing efficiency, longevity, and safety in industrial applications. By investing in these advanced materials, businesses can not only improve their operational performance but also contribute to a more sustainable future through better resource management and reduced maintenance costs.

China Corrosion Resistant Coil Tube and Stainless Steel Coil Tube Application Now Trending

| Application Area | Material Type | Temperature Resistance (°C) | Pressure Rating (MPa) | Corrosion Resistance |

|---|---|---|---|---|

| Chemical Processing | Stainless Steel | 400 | 15 | Excellent |

| Oil & Gas | Corrosion Resistant Alloy | 350 | 20 | Very Good |

| Water Treatment | Copper-Nickel | 300 | 10 | Good |

| Heat Exchangers | Titanium | 450 | 25 | Outstanding |

| Food Processing | 304 Stainless Steel | 250 | 5 | Satisfactory |

Related Products