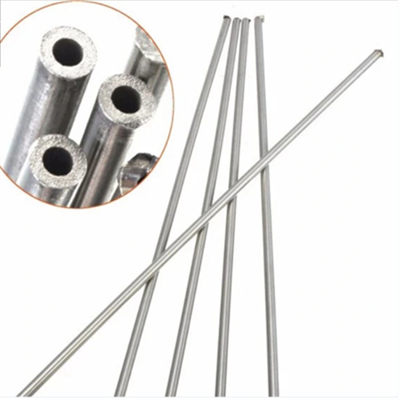

China Heat Exchanger Pipe and Boiler Tube Manufacturers for Quality Solutions

When it comes to sourcing high-quality China heat exchanger pipes and boiler tubes, I've got you covered. I understand the importance of reliable and efficient products for your industrial needs, and that's why I focus on connecting with top manufacturers in the industry. My goal is to offer you a trusted source for these essential components, ensuring that they meet strict quality standards and performance requirements. Whether you're looking to buy in bulk or need a specific size and specification, I can help simplify the purchasing process. With competitive pricing and a commitment to excellence, my partnerships with leading manufacturers allow us to provide you not just with great products but also with exceptional service. Let’s work together to fulfill your project requirements and keep your operations running smoothly. Don't hesitate to reach out for more details!

China Heat Exchanger Pipe and Boiler Tube Supplier Ahead of the Curve

In today's competitive landscape, sourcing high-quality industrial components such as heat exchanger pipes and boiler tubes is vital for enhancing operational efficiency and ensuring durability. With a commitment to excellence and a keen understanding of market demands, savvy global buyers are increasingly turning to suppliers who not only meet but exceed standard specifications. This trend reflects the broader shift towards quality over cost, where businesses recognize that investing in superior materials results in long-term savings and reliability. As industries evolve, the importance of specialized suppliers has come to the forefront. These suppliers offer advanced manufacturing capabilities, employing state-of-the-art technology and rigorous quality control processes. This ensures that each product, whether for power generation, chemical processing, or other applications, meets international standards and client-specific requirements. Moreover, the ability to provide tailored solutions gives businesses a competitive edge, allowing them to adapt to changing regulations and market dynamics more swiftly. Ultimately, forming partnerships with forward-thinking suppliers can significantly enhance operational performance and drive innovation. By staying ahead of the curve, these suppliers empower businesses to tackle emerging challenges and seize market opportunities, thereby fostering sustainable growth and success in an increasingly interconnected world. For global buyers, this strategic approach to procurement not only streamlines operations but also builds a resilient supply chain that can weather fluctuations in demand and supply.

China Heat Exchanger Pipe and Boiler Tube Supplier Ahead of the Curve

| Product Type | Material | Application | Diameter (mm) | Length (m) | Standards |

|---|---|---|---|---|---|

| Heat Exchanger Tube | Stainless Steel | Petrochemical | 25 | 6 | ASTM A213 |

| Boiler Tube | Alloy Steel | Power Generation | 38 | 12 | ASME SA192 |

| Heat Exchanger Pipe | Carbon Steel | Marine Applications | 50 | 8 | API 5L |

| Condensate Return Line | Copper Alloy | Chemical Processing | 15 | 5 | DIN 17867 |

| Superheater Tube | Chrome-Moly Steel | High Temperature Applications | 40 | 10 | EN 10216-2 |

Related Products