Top China Manufacturer of Hot Rolled Coil and Cold Rolled Coil

When it comes to sourcing top-quality steel, I know that China Hot Rolled Coil and Cold Rolled Coil are essential for various applications. As a seasoned manufacturer, I pride myself on providing reliable products that meet demanding industry standards. My coils are carefully crafted to ensure durability and precision, making them perfect for construction, automotive, and manufacturing needs. I understand the importance of competitive pricing and timely delivery, which is why I focus on streamlining the production process. Whether you're a small shop or a large corporation, I’m committed to offering the best service and materials tailored to your business requirements. With my extensive experience in the industry, I'm here to help you navigate your options and find the perfect coil solutions. Partner with me for your next project, and you'll see the difference in both quality and service. Let's make your steel supply chain efficient and reliable!

China Hot Rolled Coil and Cold Rolled Coil Products From Concept to Delivery

In the ever-evolving landscape of metal manufacturing, sourcing high-quality steel products is crucial for global procurement professionals seeking reliability and performance. Hot rolled coil and cold rolled coil products play a significant role in diverse industries, including automotive, construction, and home appliances. Understanding the journey from concept to delivery can help buyers make informed decisions and maximize the value of their investments. Hot rolled coils are produced through the process of rolling steel at high temperatures, leading to enhanced workability and a rough surface finish ideal for further processing. Conversely, cold rolled coils undergo a cooling process that results in a smoother, more precise finish, making them suitable for applications where appearance and tighter tolerances are essential. As global demand for these products grows, leveraging innovative production techniques and stringent quality control is key to meeting the industry standards and customer requirements. From initial concept design to timely delivery, a comprehensive supply chain approach ensures that every step of production meets global expectations. This includes sourcing premium raw materials, employing advanced manufacturing technologies, and adhering to international quality certifications. Such an approach not only streamlines operations but also fosters relationships built on trust and reliability, allowing procurement managers to source their requirements confidently while balancing cost and quality.

China Hot Rolled Coil and Cold Rolled Coil Products From Concept to Delivery

| Product Type | Description | Applications | Production Process | Delivery Timeline |

|---|---|---|---|---|

| Hot Rolled Coil | Produced through high temperature rolling process | Construction, automotive, and heavy machinery | Heating slabs, rolling, and cooling | 4-6 weeks |

| Cold Rolled Coil | Processed at room temperature for enhanced precision | Appliances, electronics, and furniture | Cold reduction, annealing, and tempering | 6-8 weeks |

| Galvanized Hot Rolled Coil | Hot rolled coil coated with zinc for corrosion resistance | Roofing, fencing, and automotive applications | Hot rolling followed by galvanization | 5-7 weeks |

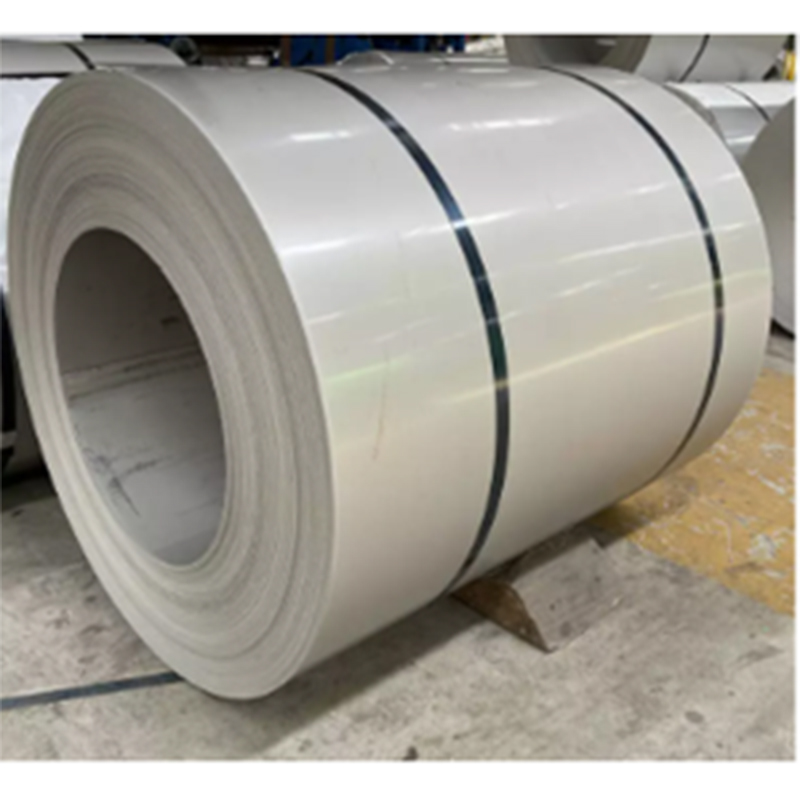

| Pre-painted Cold Rolled Coil | Cold rolled coils painted before forming | Household appliances and decorative applications | Cold rolling, painting, and curing | 6-10 weeks |

Related Products