China Manufacturer of Stainless Steel Coil Tubing & 304 Coil Tube

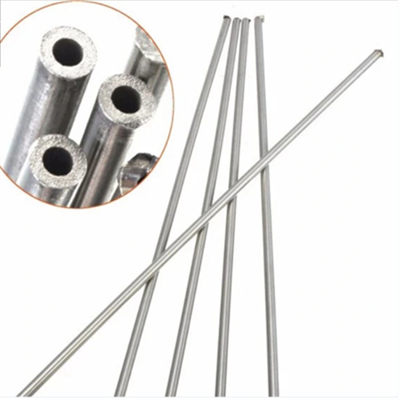

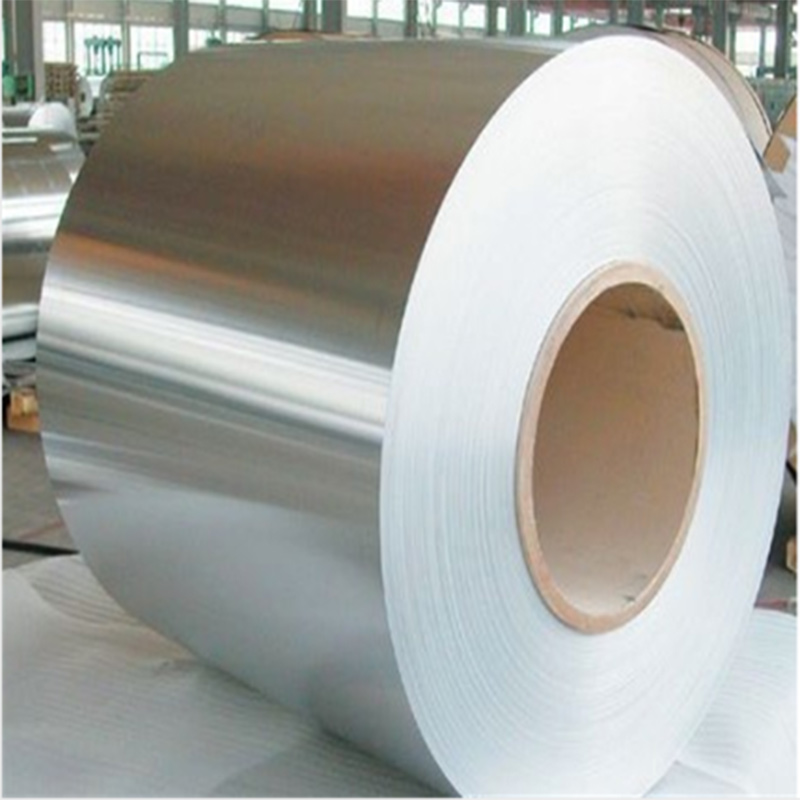

As a buyer in need of top-quality stainless steel solutions, I can assure you that our China Stainless Steel Coil Tubing and 304 Stainless Steel Coil Tube stand out in the market. Manufactured with precision, these coils are crafted to meet the highest industry standards, ensuring durability and reliability for diverse applications. When I examine the specifications, I find that the corrosion resistance of 304 stainless steel makes it ideal for various environments, from construction to automotive industries. Our manufacturing process prioritizes quality and efficiency, giving me confidence in every order. Whether I’m sourcing for a large-scale project or just in need of dependable materials, I know I can rely on our offerings. With competitive pricing and prompt delivery, partnering with a reputable Chinese manufacturer will make my procurement process smooth and effortless. Don't miss the chance to elevate your projects with our premium stainless steel coil tubing solutions!

China Stainless Steel Coil Tubing and 304 Stainless Steel Coil Tube Is The Best Winning in 2025

As we approach 2025, the demand for high-quality stainless steel coil tubing continues to surge globally, driven by various industries ranging from construction to automotive. Among the numerous options available, 304 stainless steel coil tubes stand out for their exceptional corrosion resistance, durability, and versatility. These properties make them ideal for applications that require both structural integrity and aesthetic appeal. In a competitive market, sourcing from reliable suppliers becomes crucial for procurement professionals. China's stainless steel coil tubing industry is poised to lead in quality and innovation, offering advanced manufacturing processes that ensure precision and consistency. The ability to customize products to meet specific requirements further enhances the appeal of sourcing from this region, aligning with the evolving needs of global buyers who prioritize both performance and cost efficiency. By choosing 304 stainless steel coil tubes, businesses can enjoy long-term benefits, including reduced maintenance costs and improved operational efficiency. As we look ahead to 2025, strategic partnerships with reputable manufacturers will be essential for those looking to capitalize on the robust growth in global markets, making now the perfect time to explore opportunities in the stainless steel coil tubing sector.

China Stainless Steel Coil Tubing and 304 Stainless Steel Coil Tube Is The Best Winning in 2025

| Material Type | Application | Diameter (mm) | Wall Thickness (mm) | Corrosion Resistance | Heat Resistance |

|---|---|---|---|---|---|

| 304 Stainless Steel | Oil & Gas | 25 | 2 | Good | Up to 870°C |

| 316L Stainless Steel | Chemical Processing | 30 | 2.5 | Excellent | Up to 925°C |

| Duplex Stainless Steel | Marine Applications | 40 | 3 | Very Good | Up to 600°C |

| 430 Stainless Steel | Automotive | 20 | 1.5 | Fair | Up to 800°C |

| 304L Stainless Steel | Food Processing | 15 | 1 | Good | Up to 870°C |

Related Products