Electropolished Tubing Manufacturer in China: Quality & Precision Solutions

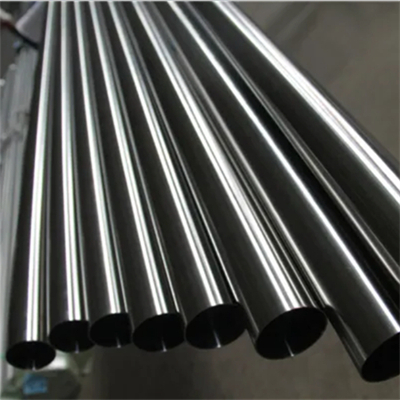

When it comes to quality and precision, electropolished tubing is essential for various industries. I’ve seen firsthand how crucial it is for projects requiring superior surface finishes and corrosion resistance. Our electropolished tubing, sourced directly from leading manufacturers in China, guarantees the highest standards of production. We know that B2B purchasers value reliability and performance, and that’s why our tubing is designed to meet diverse applications from pharmaceuticals to food processing. The electropolishing process enhances not only the aesthetic appeal but also the functional aspects, ensuring cleanliness and durability. Whether you’re seeking tubing for critical applications or standard projects, our solutions cater to your specific needs. Partnering with us means accessing premium products while enjoying competitive pricing and exceptional service. Let’s elevate your business with top-notch electropolished tubing that truly makes a difference in your operational success.

Electropolished Tubing Stands Out Trusted by Pros

Electropolished tubing has emerged as a preferred choice among professionals across various industries, thanks to its unparalleled combination of aesthetics and performance. This specialized process not only enhances the surface finish of the tubing but also significantly improves its corrosion resistance, making it an ideal option for applications in food processing, pharmaceuticals, and aerospace. The smooth, shiny surface minimizes the adherence of contaminants, ensuring that products remain clean and safe throughout their lifecycle. The trusted reputation of electropolished tubing stems from its ability to meet stringent industry standards while providing exceptional durability. Global buyers are increasingly recognizing the value of investing in quality materials that enhance operational efficiency and compliance with regulatory requirements. As industries become more demanding, the need for reliable suppliers of high-performance electropolished tubing has never been more critical. By choosing a provider with a proven track record, procurement professionals can ensure they are sourcing materials that not only meet their immediate needs but also contribute to long-term success in competitive markets. In an era where quality and reliability are paramount, electropolished tubing stands out as a superior solution for those looking to elevate their manufacturing processes. The fusion of cutting-edge technology and rigorous quality control measures ensures that customers receive a product that not only meets but exceeds expectations. As global demand continues to rise, companies are encouraged to explore the benefits of electropolished tubing and partner with reputable manufacturers who can deliver consistent quality and performance.

Electropolished Tubing Stands Out Trusted by Pros

| Material | Diameter (inches) | Wall Thickness (inches) | Finish Type | Applications |

|---|---|---|---|---|

| 304 Stainless Steel | 1.00 | 0.035 | Electropolished | Food Processing |

| 316L Stainless Steel | 1.50 | 0.049 | Electropolished | Pharmaceutical |

| Duplex Stainless Steel | 2.00 | 0.065 | Electropolished | Chemical Processing |

| Titanium | 0.75 | 0.025 | Electropolished | Aerospace |

| Nickel Alloy | 3.00 | 0.080 | Electropolished | Oil and Gas |

Related Products