Flexible Tube Stainless Steel: Top Manufacturers and Best Options Available

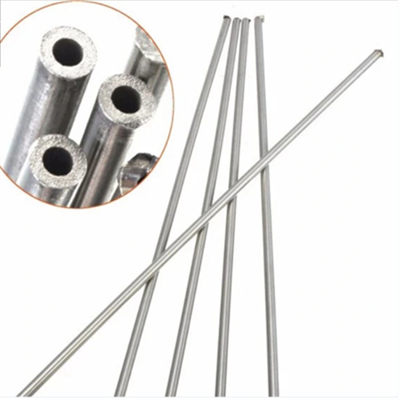

When I think about flexibility and durability in tubing, the Flexible Tube Stainless Steel tops my list. This versatile product is perfect for a range of industrial applications, thanks to its exceptional strength and resistance to corrosion. I’ve seen firsthand how reliable and efficient these tubes are, making them an ideal choice for any B2B project. If you are in the market to buy, you'll find that many manufacturers offer various sizes and configurations to meet your specific needs. I appreciate how easy it is to customize these tubes, ensuring they fit seamlessly into my projects. Having worked with numerous suppliers, I can confidently say that investing in high-quality stainless steel tubes not only enhances performance but also guarantees longevity. Don't settle for less when it comes to your industrial needs; choose Flexible Tube Stainless Steel for superior quality and unmatched flexibility that truly makes a difference!

Flexible Tube Stainless Steel Products Guarantees Peak Performance

In the ever-evolving landscape of industrial materials, the demand for flexible tube stainless steel products has surged, driven by their unmatched durability and versatility. These products are engineered to perform under the most challenging conditions, ensuring peak performance in a variety of applications. From automotive and aerospace to food processing and pharmaceuticals, flexible stainless steel tubes stand out for their corrosion resistance, strength, and adaptability. Adopting flexible tube technology allows manufacturers to optimize their processes by reducing the risk of leaks and failures in critical systems. This not only leads to enhanced operational efficiency but also minimizes downtime and maintenance costs. As global procurement becomes increasingly competitive, investing in high-quality stainless steel solutions can provide a significant edge, ensuring products meet international standards while keeping pace with innovation. Moreover, the sustainability aspect cannot be overlooked. Stainless steel is recyclable and can be reused in various applications, aligning with the global shift towards eco-friendly practices. As businesses worldwide prioritize sustainable production methods, sourcing flexible tube stainless steel products not only supports operational goals but also contributes to a greener future. This combination of performance, reliability, and sustainability solidifies the relevance of flexible tube stainless steel products in today’s industrial market.

Flexible Tube Stainless Steel Products Guarantees Peak Performance

| Product Type | Diameter (mm) | Length (m) | Wall Thickness (mm) | Max Temperature (°C) | Application Area |

|---|---|---|---|---|---|

| Flexible Tube A | 25 | 2 | 1.5 | 200 | Food Industry |

| Flexible Tube B | 40 | 3 | 2 | 250 | Chemical Processing |

| Flexible Tube C | 50 | 5 | 2.5 | 300 | Oil and Gas |

| Flexible Tube D | 60 | 4 | 3 | 180 | Pharmaceuticals |

Related Products