Top Manufacturers of Stainless Intake Tubing for Your Needs

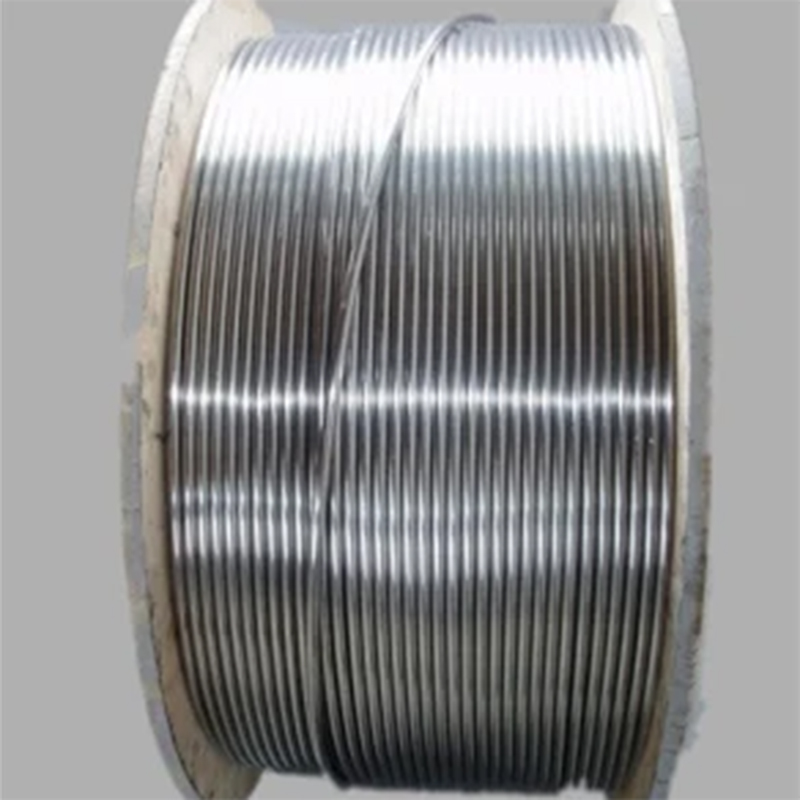

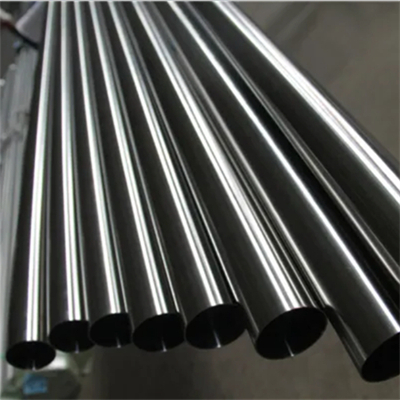

As a business owner, I understand the importance of having reliable, high-quality Stainless Intake Tubing for your operations. When I'm in the market to buy, I prioritize durability and performance. That’s why I always choose products from leading manufacturers known for their commitment to excellence. Our stainless intake tubing is designed to meet various industrial standards, ensuring it can withstand harsh environments and provide long-lasting service. With its corrosion-resistant properties, it offers peace of mind in any application. When I need to ensure my systems run efficiently, this is the go-to choice. Connecting with reputable suppliers and manufacturers has always made my procurement process smoother. Let's take your projects to the next level with stainless intake tubing that truly delivers on quality and reliability.

Stainless Intake Tubing Your Trusted OEM Partner Factory-Direct Excellence

When it comes to sourcing high-quality stainless intake tubing, partnering with a reliable OEM manufacturer can greatly enhance your operational efficiency and product offerings. Our factory-direct approach ensures that you receive premium materials without the intermediaries, translating into cost-effectiveness and timely deliveries. Companies across various industries—from automotive to aerospace—are increasingly seeking solutions that combine durability with precision. We specialize in the fabrication of stainless steel intake tubing, utilizing advanced techniques and rigorous quality control measures to guarantee that each piece meets the highest standards. Our products are designed to withstand extreme conditions, ensuring the longevity and performance essential for any robust application. As a trusted OEM partner, we are committed to understanding your unique project requirements, enabling us to provide tailored solutions that align with your specific needs. In addition to premium quality, our commitment to sustainability and innovation ensures that your sourcing process not only meets current demands but also anticipates future trends. This forward-thinking approach positions us as the partner of choice for global buyers looking to stay ahead in a competitive market. Experience the excellence of factory-direct sourcing and discover how we can elevate your project outcomes with unparalleled quality and service.

| Dimension (mm) | Material | Finish | Application | Certification |

|---|---|---|---|---|

| 25 x 1.5 | 304 Stainless Steel | Polished | Automotive | ISO 9001 |

| 30 x 2.0 | 316 Stainless Steel | Brushed | Marine | ASTM |

| 20 x 1.0 | 304L Stainless Steel | Mirror Finish | Food Industry | FDA Approved |

| 40 x 3.0 | 310 Stainless Steel | Electropolished | Chemical Processing | NACE |

| 50 x 4.0 | 321 Stainless Steel | Passivated | Oil & Gas | API Spec |

Related Products