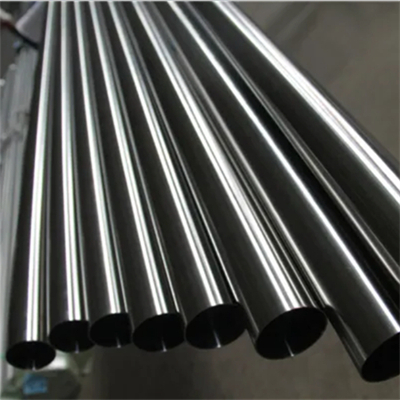

China Manufacturer of Thin Wall Stainless Steel Tubing & 201 Tubing

As a leading manufacturer of China Thin Wall Stainless Steel Tubing and 201 Thin Wall Stainless Steel Tubing, I understand the unique needs of B2B purchasers. Our tubing is designed with precision, ensuring durability while maintaining an ultra-lightweight profile, making it ideal for various industrial applications. I pride myself on the high quality of our products, using top-tier materials that meet rigorous standards. Whether you are fabricating components for automotive, aerospace, or construction, my stainless steel tubing provides the reliability and strength you need. I am committed to delivering tailored solutions and exceptional customer service to support your purchasing decisions. Partnering with us means you get not just superior products, but a relationship built on trust and dedication to your success. Every order is fulfilled promptly, ensuring you can meet your project timelines without hassle. Let's work together to elevate your processes with our China-manufactured stainless steel tubing!

China Thin Wall Stainless Steel Tubing and 201 Thin Wall Stainless Steel Tubing Pioneers in the Field Where Innovation Meets 2025

In the fast-evolving landscape of stainless steel tubing, China stands at the forefront with its innovation and production capabilities, particularly in the realm of thin-wall stainless steel tubing. The market is increasingly demanding high-performance materials that not only meet but exceed rigorous standards. This is where thin-wall stainless steel tubing shines, offering a perfect combination of strength and lightweight characteristics—ideal for a diverse range of applications, from automotive to aerospace, and beyond. As we approach 2025, pioneers in this field are leveraging advanced manufacturing techniques and cutting-edge technology to produce tubing that meets the specific needs of global buyers. The focus on quality and sustainability is driving innovations, enabling manufacturers to provide solutions that enhance performance while minimizing environmental impact. Buyers can expect enhanced precision, durability, and adaptability in products, ensuring they can meet the growing demands of their respective industries. For global procurement professionals, understanding the capabilities of thin-wall stainless steel tubing is essential to stay competitive. Engaging with manufacturers that prioritize innovation and quality will provide an edge in sourcing the right materials for future projects. As the industry evolves, staying informed and adapting to these changes will be key to making successful purchasing decisions.

China Thin Wall Stainless Steel Tubing and 201 Thin Wall Stainless Steel Tubing Pioneers in the Field Where Innovation Meets 2025

| Feature | Description | Application | Material Grade | Diameter Range (mm) | Wall Thickness (mm) |

|---|---|---|---|---|---|

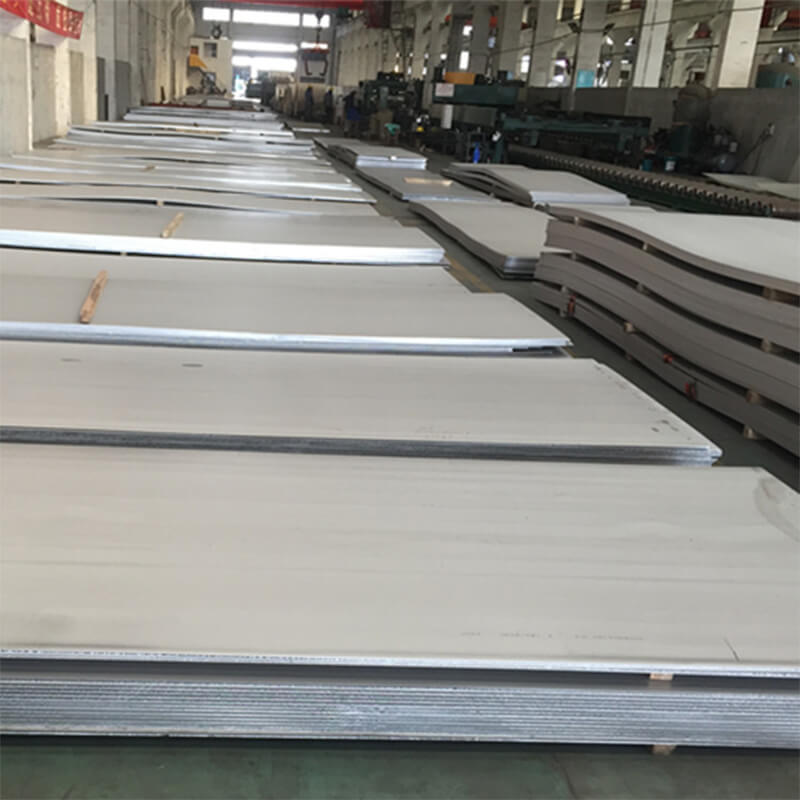

| Corrosion Resistance | Excellent resistance to corrosion, suitable for various environments. | Automotive, construction, and aerospace industries. | 201 | 6 - 40 | 0.5 - 3.0 |

| Weldability | Good weldability with proper techniques. | Pipe fittings and structural applications. | 304 | 4 - 32 | 0.7 - 2.5 |

| Temperature Resistance | Maintains strength at elevated temperatures. | Heat exchangers and boilers. | 316L | 5 - 50 | 0.6 - 2.0 |

| Strength | High tensile strength suitable for heavy-duty applications. | Structural tubing and support systems. | 409 | 8 - 60 | 1.0 - 3.5 |

Related Products