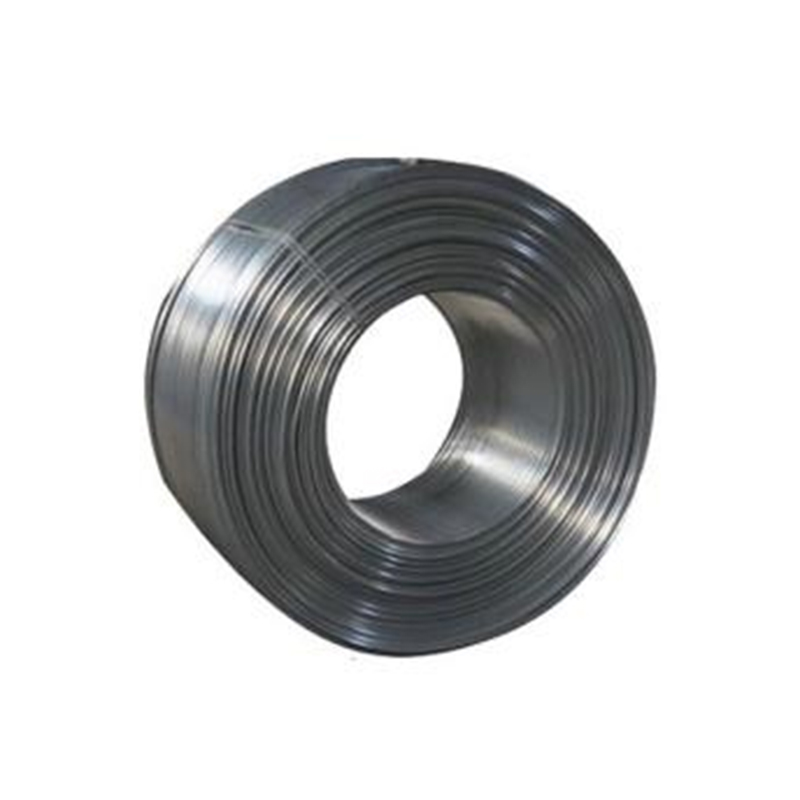

Coiled Tubing Inspection by Leading China Manufacturer for Superior Quality

When I think about coiled tubing inspection, I picture precision and reliability woven into every detail. In the heart of China, we specialize in providing top-notch coiled tubing inspection services tailored for manufacturers like you. Our advanced techniques and state-of-the-art equipment ensure that your operations run smoothly and efficiently, which ultimately boosts your productivity. With an experienced team dedicated to upholding the highest standards, we guarantee thorough inspections that identify potential issues before they escalate. We prioritize your needs, offering solutions that align with your manufacturing goals. Choosing us means you’re not just getting a service; you’re forming a partnership committed to your success. Let’s elevate your operations together! Reach out today to find out how our coiled tubing inspection services can enhance your performance and ensure your projects in China are on the cutting edge.

Coiled Tubing Inspection Application Dominates

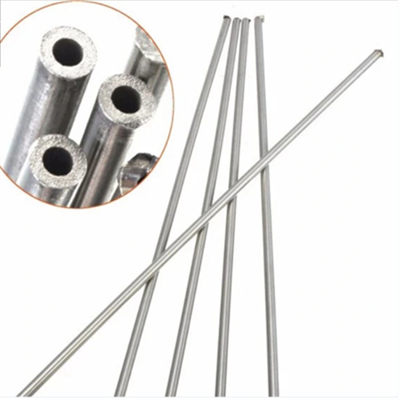

Coiled tubing inspection applications have emerged as a crucial sector in the oil and gas industry, particularly for enhancing operational efficiency and ensuring safety standards. With the growing complexities of drilling operations, the need for effective inspection techniques has never been greater. Coiled tubing allows for continuous advancements in downhole operations, enabling swift deployment while minimizing risks and downtime. Companies worldwide are increasingly investing in sophisticated inspection technologies to monitor tubing integrity, detect anomalies, and prevent costly failures, thereby optimizing their production processes. In this global market, advanced materials play a fundamental role in the development of durable and reliable coiled tubing solutions. Explorations in innovative metal materials have led to improved corrosion resistance and strength, which are vital for withstanding the harsh conditions encountered in subsurface operations. By focusing on R&D and utilizing state-of-the-art manufacturing techniques, industry leaders are paving the way for the next generation of coiled tubing inspection applications. The integration of real-time monitoring systems further enhances the ability to predict maintenance needs, thereby extending the life of equipment and reducing operational costs. As demand for efficient and effective coiled tubing solutions continues to rise, it presents a significant opportunity for procurement professionals worldwide. By sourcing high-quality materials and cutting-edge inspection technologies, companies can achieve unmatched performance and reliability in their operations. This shift not only enhances productivity but also reinforces environmental sustainability through reduced waste and enhanced resource management in the industry. Exploring strategic partnerships and investing in innovative solutions will enable businesses to stay ahead in the dynamic landscape of coiled tubing applications.

Coiled Tubing Inspection Application Dominates

| Inspection Type | Technology Used | Application Area | Benefits | Challenges |

|---|---|---|---|---|

| Visual Inspection | CCTV Cameras | Wellbores | Quick assessment of condition | Limited detail, low light issues |

| Ultrasonic Testing | Ultrasonic Sensors | Pipelines | Detects wall thickness variations | Require skilled operators |

| Magnetic Particle Inspection | Magnetic Fields | Metal Components | Surface flaw detection | Limited to surface defects |

| Eddy Current Testing | Eddy Current Sensors | Non-ferrous Metals | Detects conductive material flaws | Calibration required for accuracy |

| Pressure Testing | Hydrostatic Methods | Well Control Equipment | Ensures integrity of equipment | Requires downtime, can be expensive |

Related Products