Cold Rolled Stainless Steel Coil 201 304 316 - Trusted Manufacturers

When it comes to sourcing cold rolled stainless steel coil 201, 304, and 316, I know quality is key for your business. I've worked closely with manufacturers who specialize in producing these grades, ensuring they meet the highest standards. Our coils are designed to deliver exceptional strength and corrosion resistance, making them ideal for a variety of applications, from construction to automotive. If you're ready to buy, you'll find our pricing competitive without compromising on quality. I understand the importance of timely delivery and consistent supply, which is why partnering with reliable manufacturers is crucial. Whether you need coils for large-scale production or smaller projects, I’m here to support your needs. With our extensive range and expertise, I’ll help you make the right choice that keeps your projects on track and within budget. Let’s connect and explore how we can work together today!

cold rolled stainless steel coil 201 304 316 Service Now Trending

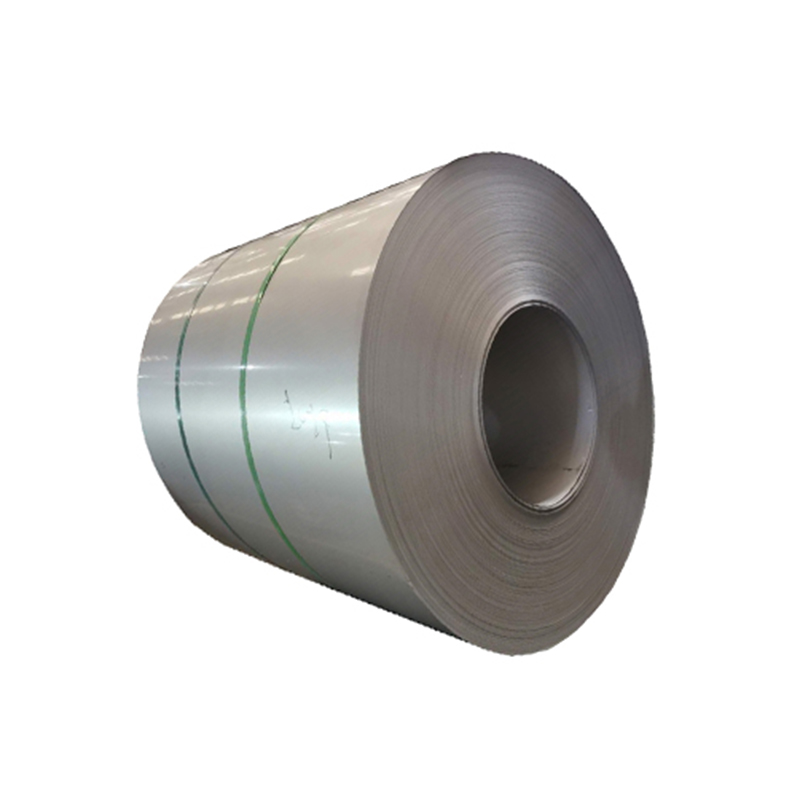

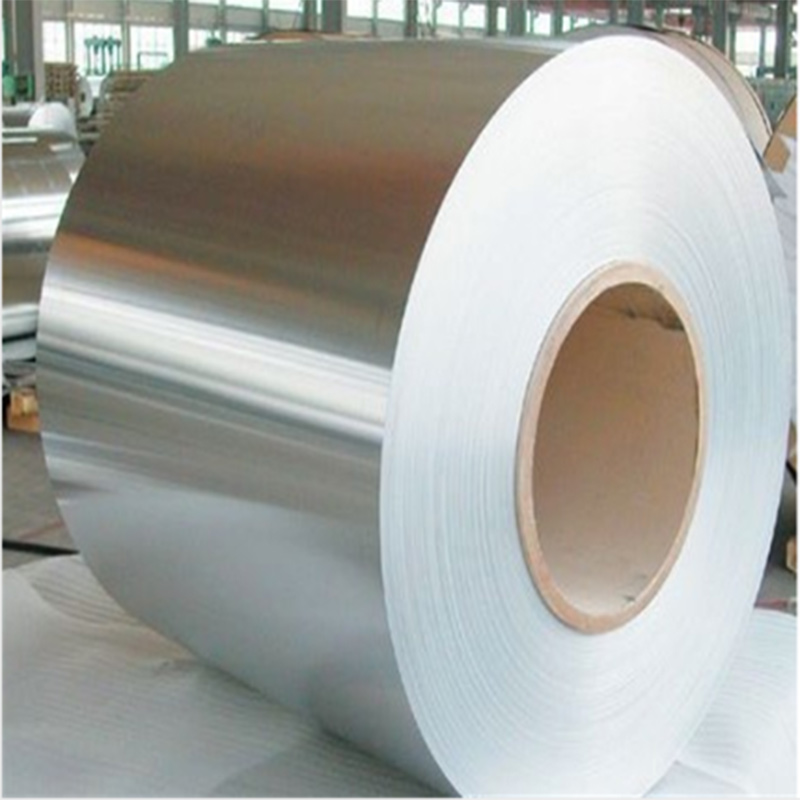

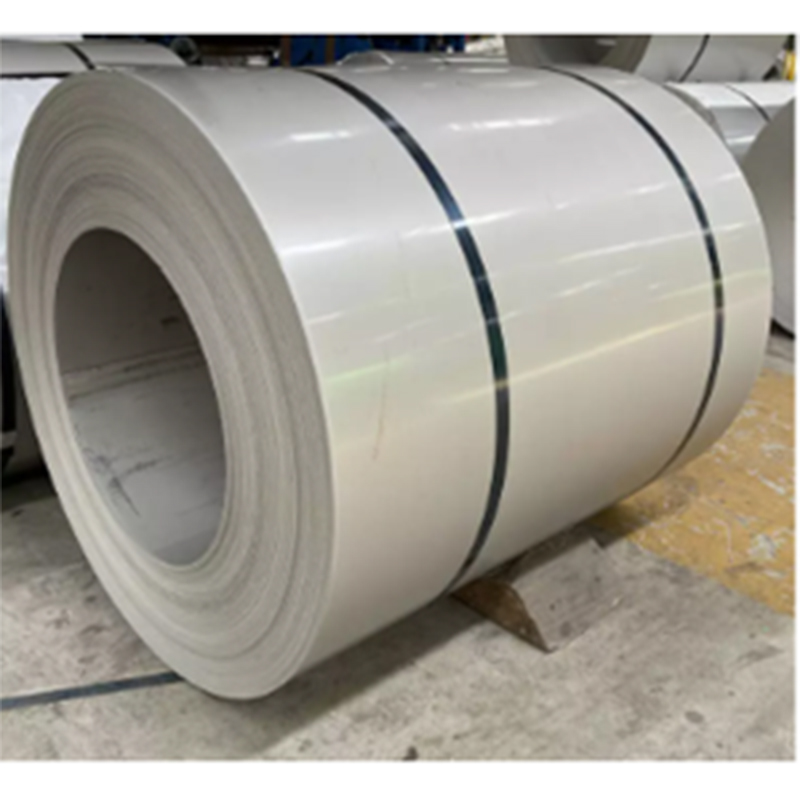

In the ever-evolving metal industry, cold rolled stainless steel coils have emerged as a preferred choice for various applications, particularly in sectors like construction, automotive, and manufacturing. The popularity of grades 201, 304, and 316 is particularly noteworthy due to their unique properties. Grade 201 offers a cost-effective alternative with good corrosion resistance, while 304 is renowned for its excellent strength and versatility. On the other hand, grade 316’s superior resistance to corrosion, especially in marine environments, makes it a leading choice for high-end applications. As global demand for these stainless steel grades surges, manufacturers are adopting innovative processing techniques to enhance product quality and performance. Trends such as sustainable production methods and the use of advanced technology in cold rolling are shaping the future of stainless steel. Buyers can benefit from this shift by sourcing high-quality steel that meets their specific requirements, ensuring durability and longevity of their end products. For procurement professionals, understanding the specific benefits and applications of cold rolled stainless steel coils is crucial for making informed purchasing decisions. By staying updated on the latest trends and developments, buyers can capitalize on opportunities in the market, thereby enhancing their supply chain efficiency and maintaining competitive advantage. The choice of stainless steel can significantly impact the quality and success of projects, making it essential to align with trusted suppliers who prioritize excellence in manufacturing and service.

Cold Rolled Stainless Steel Coil 201, 304, 316 Service Now Trending

| Material Type | Thickness (mm) | Width (mm) | Length (m) | Finish | Applications |

|---|---|---|---|---|---|

| 201 | 0.5 | 1000 | 2.0 | 2B | Kitchenware, Building |

| 304 | 1.0 | 1250 | 3.0 | BA | Food Industry, Medical Equipment |

| 316 | 1.5 | 1500 | 4.0 | No. 1 | Marine Applications, Chemical Processing |

Related Products