Premium 1 2 Stainless Steel Coil Tubing Manufacturer in China

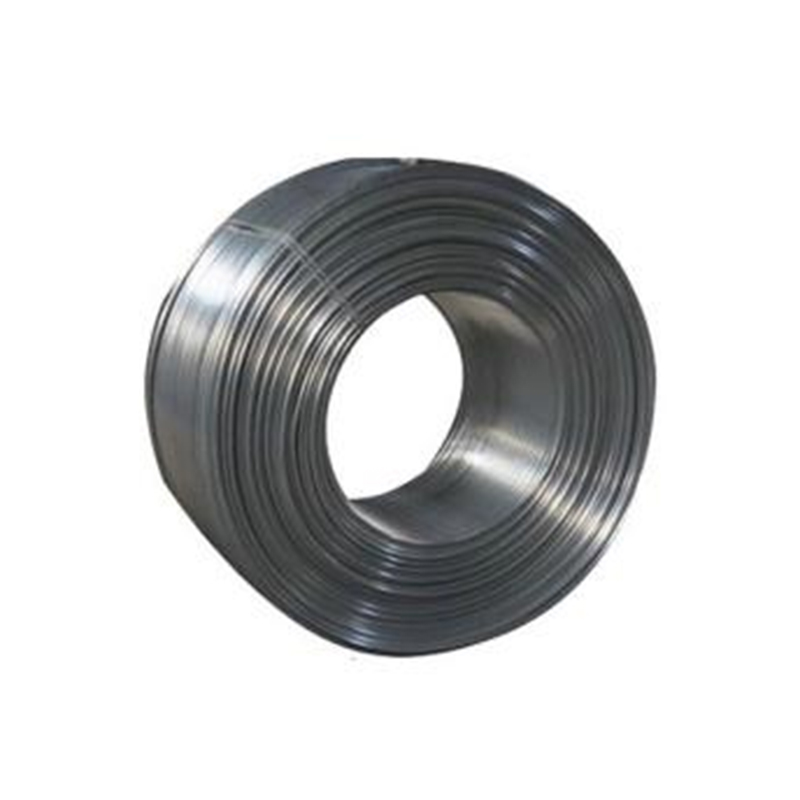

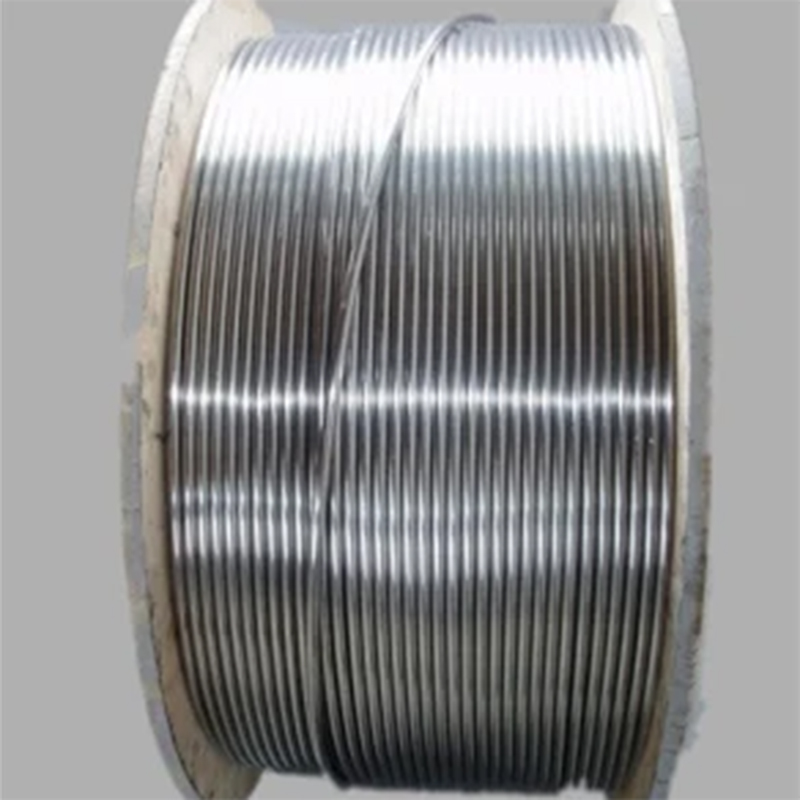

When I think of quality and reliability, 1 2 Stainless Steel Coil Tubing immediately comes to mind. As a seasoned buyer, I know how crucial it is to work with a trustworthy manufacturer. That’s why sourcing from China has always been a preferred choice for me. The stainless steel coil tubing we offer is not only durable but also exhibits excellent corrosion resistance, making it ideal for various industrial applications. I appreciate the versatility of these coils—they can be easily customized to meet specific requirements, ensuring that they fit perfectly into my projects. Additionally, I’ve experienced prompt delivery times and competitive pricing, which are essential factors for keeping my operations running smoothly. Whether it’s for oil and gas, automotive, or construction, I find that this product consistently meets my expectations for both quality and performance. If you’re in the market for reliable stainless steel solutions, don’t hesitate to reach out to a reputable manufacturer in China.

1 2 Stainless Steel Coil Tubing Service Where Innovation Meets 2025

In the ever-evolving landscape of industrial materials, stainless steel coil tubing stands out as a critical component in various sectors, from automotive to energy. As we look towards 2025, the focus on innovation and quality in stainless steel solutions is more pertinent than ever. The advancements in manufacturing processes have led to enhancements in durability, resistance to corrosion, and versatility of application. This evolution not only meets the demands of modern infrastructure but also aligns with the sustainability goals of global industries. At the forefront of this innovation is the employment of cutting-edge technologies that streamline production and enhance product performance. These developments ensure that stainless steel coil tubing is not just a material choice, but a strategic advantage for procurement teams looking to optimize supply chains. From precise coil forming to advanced welding techniques, the emphasis on quality control guarantees that these products can withstand the rigors of demanding environments while maintaining efficiency and safety. As we move towards 2025, the collaboration between suppliers and industries will be crucial. Global buyers can leverage the expertise and advancements in stainless steel coil tubing to ensure their projects meet not only their immediate needs but also future challenges. By prioritizing innovation and sustainability, these strategic partnerships can lead to the development of resilient infrastructures that stand the test of time.

1 2 Stainless Steel Coil Tubing Service Where Innovation Meets 2025

| Service Type | Description | Applications | Year Introduced |

|---|---|---|---|

| Custom Coil Tubing | Tailored stainless steel coil tubing solutions for various industries. | Oil & Gas, Chemical Processing | 2023 |

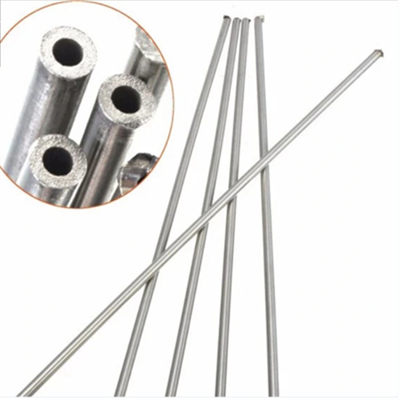

| Corrosion Resistant Tubing | High-performance tubing designed to withstand harsh environments. | Marine, Aerospace | 2024 |

| Precision Welding | Expert welding services for seamless connections and joints. | Automotive, Medical Devices | 2022 |

| Heat Treatment Services | Specialized heat treatment to enhance the properties of steel. | Manufacturing, Energy Sector | 2023 |

| Quality Assurance | Comprehensive quality testing and certification processes. | Manufacturing, Aerospace | 2025 |

Related Products