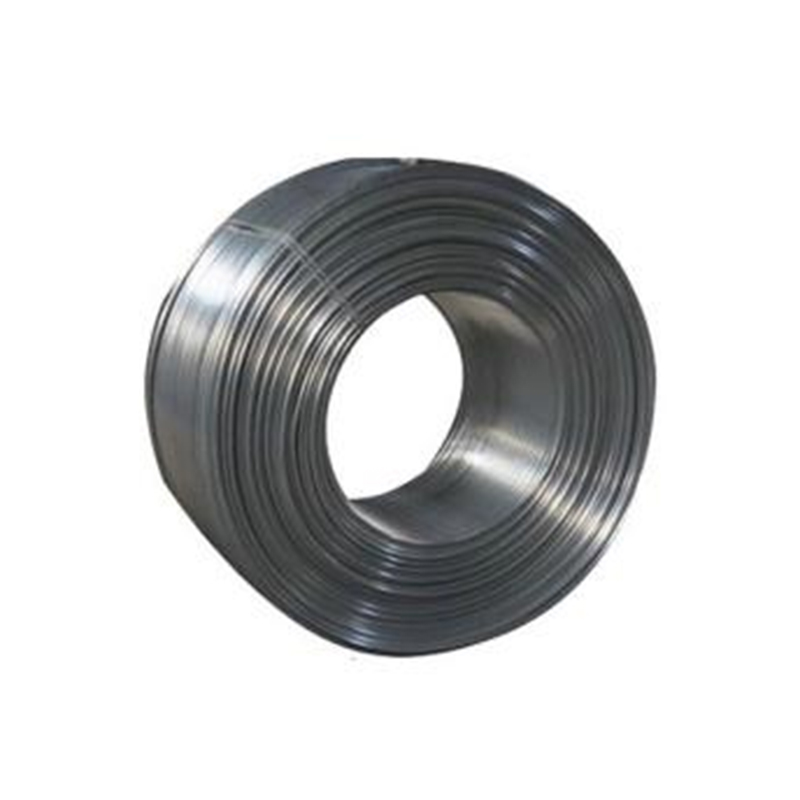

China Manufacturer of 201 304 316 Grade Coil Tubing for Quality Solutions

When it comes to high-quality coil tubing, I know the importance of selecting the right grade for your specific needs. Our 201, 304, and 316 Grade Coil Tubing are designed with durability and reliability in mind, making them perfect for various applications in your projects. As a trusted manufacturer from China, I take pride in providing products that meet rigorous industry standards. Whether you’re dealing with corrosive environments or looking for a solution that offers strength and flexibility, our coil tubing fits the bill. Plus, with competitive pricing and exceptional customer service, I’m here to help you find exactly what you need. Let's work together to ensure your projects run smoothly and efficiently!

201 304 316 Grade Coil Tubing in 2025 Factory-Direct Excellence

In recent years, the demand for high-quality coil tubing has surged across various industries, particularly in oil and gas, construction, and manufacturing. The use of 201, 304, and 316 grade stainless steel coil tubing presents a decisive advantage due to their excellent corrosion resistance and structural integrity. With innovations in production practices, the world is poised to witness exceptional advancements in coil tubing by 2025, focusing on factory-direct excellence. As we look towards the future, the emphasis will increasingly be on sustainable manufacturing processes that reduce waste and enhance product quality. The seamless integration of technology in production lines is expected to elevate the standards, offering global buyers reliable solutions that not only meet but exceed their expectations. The essence of factory-direct excellence lies in maintaining direct communication between manufacturers and procurement specialists, ensuring transparency, cost-effectiveness, and timeliness in delivery. For global purchasers, sourcing from manufacturers committed to quality control and innovation can provide a competitive edge. Understanding the unique properties and applications of 201, 304, and 316 grades will empower businesses to make informed decisions that align with industry standards and project requirements. The future of coil tubing is bright, and buyers can expect to find superior products that cater to their specific needs while supporting their sustainability goals.

201 304 316 Grade Coil Tubing in 2025 Factory-Direct Excellence

| Material Grade | Outer Diameter (mm) | Wall Thickness (mm) | Length (m) | Applications |

|---|---|---|---|---|

| 201 | 25 | 2 | 6 | General use, automotive parts |

| 304 | 30 | 1.5 | 12 | Food processing, chemical equipment |

| 316 | 40 | 3 | 8 | Marine applications, medical devices |

Related Products