China 2205 Down Hole Chemical Injection Tubing Manufacturer Solutions

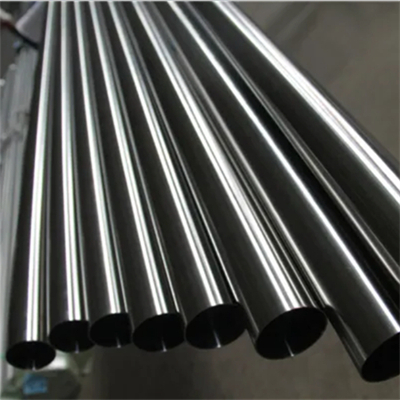

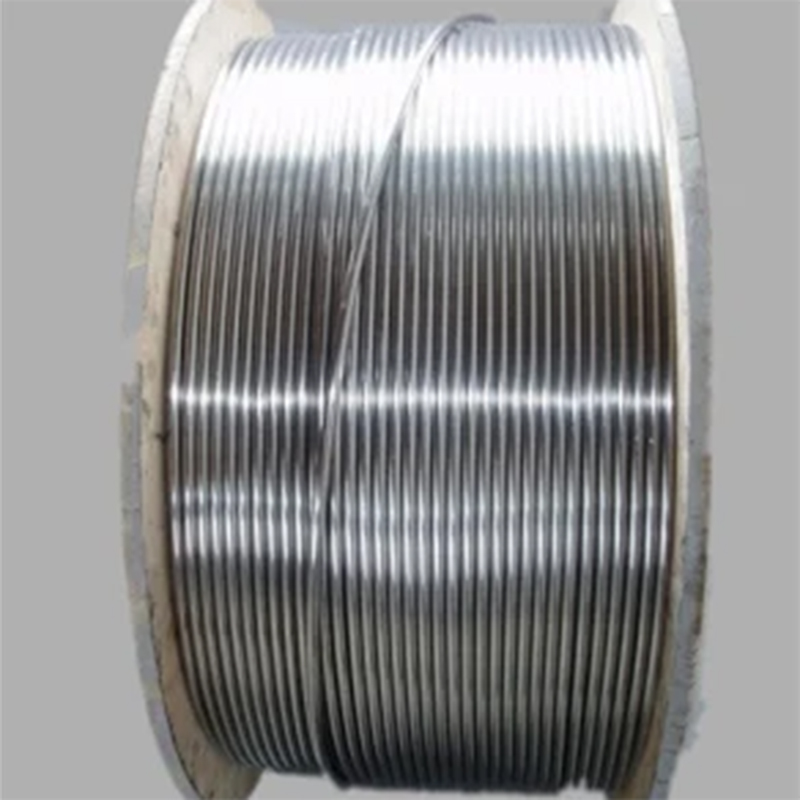

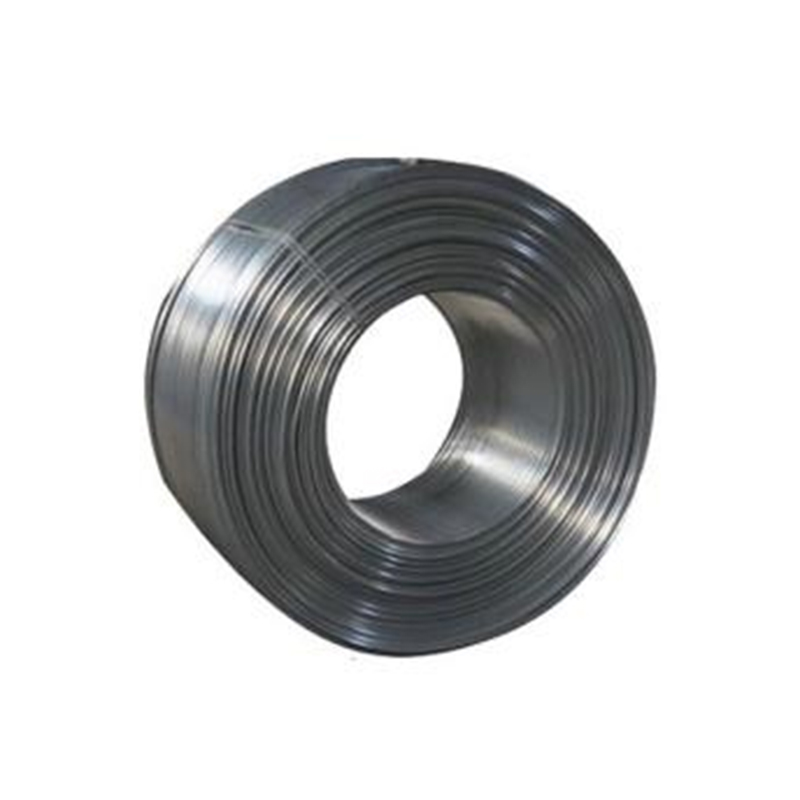

When it comes to reliable chemical injection solutions, I trust the China 2205 Down Hole Chemical Injection Tubing. This tubing is designed to perform under high pressures and harsh environments, making it ideal for demanding applications in the oil and gas industry. As a manufacturer, I've seen firsthand the quality and durability that 2205 materials bring, ensuring longevity and reduced downtime. Whether you're looking to optimize your operations or improve efficiency, this tubing stands out with its exceptional resistance to corrosion and stress. I've found it really helps in maintaining consistent chemical injection rates, which is crucial for effective operations. By choosing China 2205 Down Hole Chemical Injection Tubing, I'm confident you’re making a smart investment in your project’s success. For those seeking a dependable solution that meets industry standards, trust me—you won’t be disappointed.

China 2205 Down Hole Chemical Injection Tubing Application Is The Best

The 2205 down hole chemical injection tubing from China is revolutionizing the oil and gas industry, offering unmatched reliability and versatility for various applications. This advanced tubing leverages the superior properties of duplex stainless steel, characterized by its excellent strength, corrosion resistance, and weldability. With the rising demand for efficient chemical injection solutions to optimize production, the 2205 tubing stands out as a top choice for global buyers seeking durability and performance in harsh environments. One of the key benefits of using 2205 down hole chemical injection tubing lies in its ability to withstand high pressures and temperatures while resisting corrosive fluids commonly encountered in oilfield operations. This tubing is engineered to meet rigorous industry standards, ensuring safety and reliability during critical operations. Global buyers searching for effective solutions to enhance their production processes will find that investing in high-quality chemical injection tubing can significantly reduce downtime and maintenance costs. Moreover, the integration of cutting-edge technology in the manufacturing process ensures that this tubing delivers superior performance in both offshore and onshore environments. As the energy sector increasingly focuses on sustainability and efficiency, 2205 down hole chemical injection tubing positions itself as an essential asset for companies aiming to improve their operational workflows while minimizing environmental impact. For those considering procurement options in the global market, choosing the right tubing solution is paramount to achieving long-term success and sustainability in their operations.

China 2205 Down Hole Chemical Injection Tubing Application Is The Best

| Application Area | Fluid Type | Temperature Range (°C) | Pressure Rating (MPa) | Corrosion Resistance |

|---|---|---|---|---|

| Oil & Gas Wells | Chemical Injection Fluids | -20 to 120 | 10 | Excellent |

| Geothermal Applications | Hot Water | 60 to 150 | 15 | Good |

| Chemical Processing | Acids and Bases | -10 to 100 | 20 | Very Good |

| Offshore Applications | Seawater | 0 to 90 | 25 | Excellent |

Related Products