- Getting started

- China 304 Down Hole Chemical Injection Tubing and Stainless Steel 304 Capillary Tubing

China 304 Down Hole Chemical Injection Tubing & Stainless Steel Manufacturer

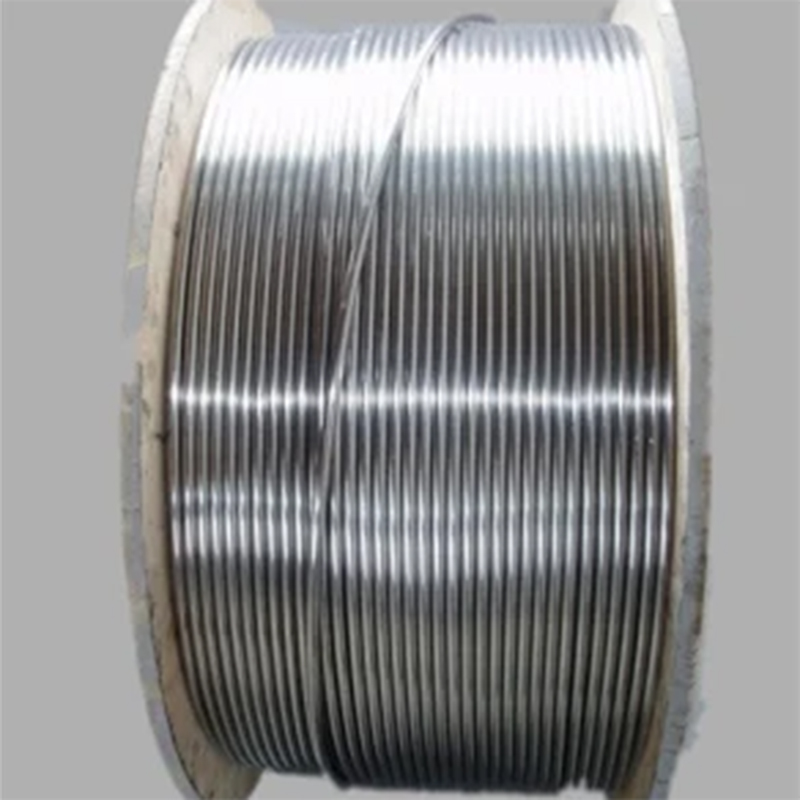

When exploring the best solutions for your down hole operations, consider our China 304 Down Hole Chemical Injection Tubing and Stainless Steel 304 Capillary Tubing. I’ve seen firsthand how these products enhance efficiency and reliability in demanding environments. Our tubing is crafted to withstand harsh conditions, featuring excellent corrosion resistance and durability, ensuring a long service life. As a trusted manufacturer, we focus on quality and precision, delivering reliable products that meet stringent industry standards. I understand the importance of finding the right fit for your projects, and our products have been designed with your needs in mind. Each piece of tubing undergoes rigorous testing to ensure performance and safety, making it an ideal choice for various applications. By choosing our China-manufactured solutions, you're investing in superior quality and performance to support your operations effectively. Don't miss the opportunity to elevate your projects with our outstanding tubing solutions!

China 304 Down Hole Chemical Injection Tubing and Stainless Steel 304 Capillary Tubing Dominates More Than a Supplier - A Partner

In the competitive landscape of downhole chemical injection and capillary tubing, choosing the right supplier can significantly impact operational efficiency and project success. China's advancement in manufacturing capabilities has positioned it as a leader in producing high-quality 304 stainless steel tubing for various applications, especially in the energy sector. The combination of durability, corrosion resistance, and versatility makes 304 stainless steel an ideal choice for chemical injection processes, where reliability is paramount. As businesses increasingly seek a partner rather than just a supplier, the emphasis shifts towards forging collaborative relationships that understand unique operational needs. A dedicated partner not only understands the technical specifications required but also offers tailored solutions that enhance productivity and reduce downtime. By leveraging advanced manufacturing techniques and stringent quality control measures, suppliers in China are committed to delivering top-tier products that meet global industry standards, enabling seamless integration into existing systems. Moreover, with a focus on sustainability and eco-friendly practices, innovative companies are continuously exploring ways to enhance their products while minimizing environmental impact. This commitment ensures that clients not only receive superior products but also align with global goals for sustainable development. In a world where collaboration drives success, partnering with a reputable manufacturer can lead to long-term benefits and a competitive edge in the marketplace.

China 304 Down Hole Chemical Injection Tubing and Stainless Steel 304 Capillary Tubing Dominates More Than a Supplier - A Partner

| Product Type | Application | Material | Diameter (mm) | Length (m) | Pressure Rating (MPa) |

|---|---|---|---|---|---|

| Chemical Injection Tubing | Oil & Gas | Stainless Steel 304 | 10 | 100 | 20 |

| Capillary Tubing | Analytical Systems | Stainless Steel 304 | 1 | 50 | 30 |

| Injection Lines | Water Treatment | Stainless Steel 304 | 6 | 200 | 15 |

| Flexible Tubing | Chemical Processing | Stainless Steel 304 | 8 | 150 | 25 |

Related Products