China 304 & 316 Stainless Steel Coils Manufacturer - Quality Products

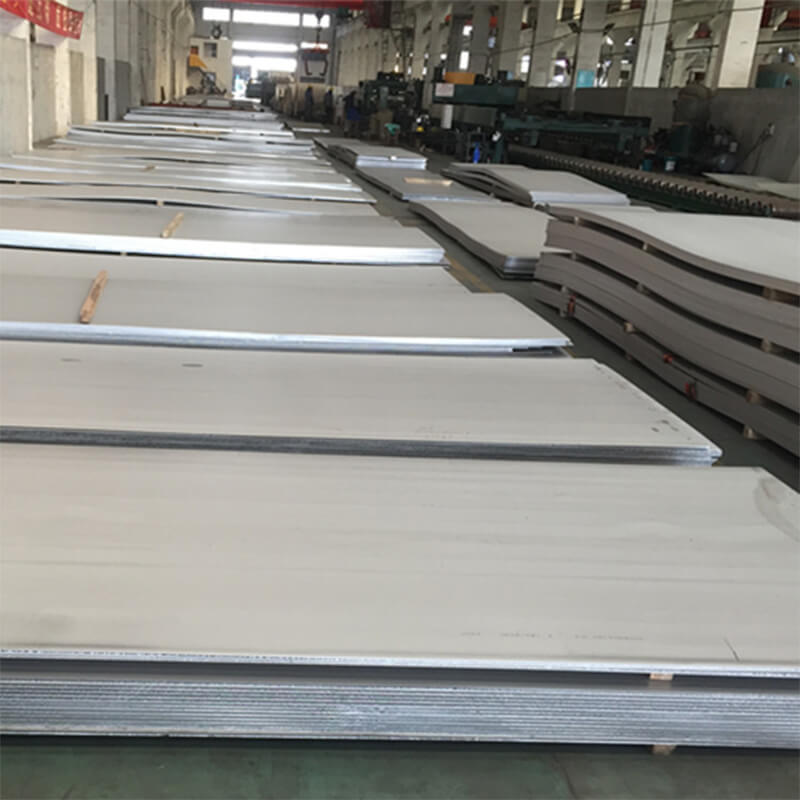

When it comes to sourcing high-quality stainless steel coils, I've found that China's 304 and 316 stainless steel coils offer exceptional value and performance. As a buyer, I appreciate the versatility of these materials. The 304 coil is perfect for general use with great corrosion resistance, while the 316 coil takes it a step further, ideal for marine environments and chemical applications. I often work directly with manufacturers in China, ensuring that I get the best prices while maintaining quality. The precision and variety in sizes available mean I can meet specific requirements for my projects without hassle. The supply chain is efficient too, which keeps lead times short. Whether you're in construction, automotive, or manufacturing, these stainless steel coils from China are an essential addition to any job. Trust me, investing in 304 and 316 coils will enhance your product durability and performance significantly.

China 304 Stainless Steel Coil and 316 Stainless Steel Coil Supplies the World\u2019s Top Brands More Than a Supplier - A Partner

In today's competitive global market, sourcing high-quality materials is essential for maintaining product excellence. China’s 304 and 316 stainless steel coils have emerged as vital components for numerous industries, ensuring that brands can uphold their reputations for durability and performance. These specific grades of stainless steel are known for their exceptional resistance to corrosion, making them ideal for applications ranging from kitchen appliances to aerospace components. Choosing the right supplier is not merely about purchasing materials; it’s about establishing a partnership that supports long-term success. By collaborating with a supplier that emphasizes quality and reliability, brands can benefit from tailored solutions that meet their unique requirements. A strong partnership ensures that businesses can access the latest innovations and adhere to industry standards without compromising on quality. Moreover, a dedicated supplier can provide insights into market trends and material advancements, allowing brands to stay ahead of the competition. The focus should be on building a synergistic relationship that not only meets immediate supply needs but also fosters growth and sustainability. In a world where supply chain efficiency is paramount, having a partner who understands the nuances of the market and can adapt to changing demands is invaluable. This approach leads to enhanced operational performance, reduced costs, and ultimately, a stronger brand presence in the global marketplace. Opting for a strategic alliance with a reputable stainless steel coil supplier can give brands the edge they need to navigate the complexities of their respective industries while ensuring quality and reliability in their product lines.

China 304 Stainless Steel Coil and 316 Stainless Steel Coil Supplies the World’s Top Brands - More Than a Supplier - A Partner

| Dimension (mm) | Thickness (mm) | Weight (kg) | Application Industries | Surface Finish |

|---|---|---|---|---|

| 1000 x 2000 | 2.0 | 5.2 | Automotive, Food Processing | 2B Finish |

| 1250 x 2500 | 3.0 | 7.8 | Pharmaceutical, Chemical | Mirror Finish |

| 1500 x 3000 | 1.5 | 4.5 | Construction, Architecture | No.1 Finish |

| 2000 x 4000 | 5.0 | 12.0 | Energy, Marine | Passivated |

Related Products