Top China Manufacturer of Stainless Flex Tubing for Your Needs

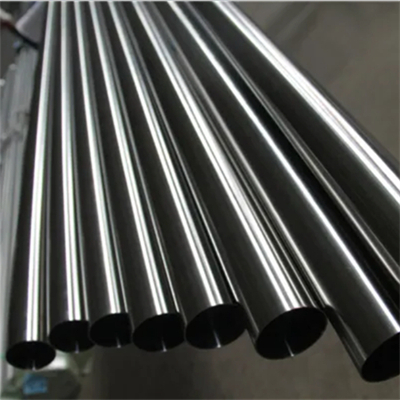

When searching for high-quality stainless flex tubing, I understand the importance of reliability and performance in your projects. Sourced directly from trusted manufacturers in China, our stainless flex tubing is designed to meet industry standards while offering flexibility and durability for a variety of applications. I've seen firsthand how this tubing can withstand extreme temperatures and pressures, making it ideal for automotive, aerospace, and industrial uses. With our extensive experience in manufacturing, I can assure you that every piece is crafted with precision to ensure optimal performance. Plus, the competitive pricing we offer means you can achieve top-notch solutions without breaking the bank. Whether you need custom sizes or standard options, I'm here to help you find exactly what you’re looking for. Partner with us for your stainless flex tubing needs, and let's elevate your projects together!

Stainless Flex Tubing Your Trusted OEM Partner More Than a Supplier - A Partner

In the fast-evolving world of manufacturing and supply chain management, the role of an Original Equipment Manufacturer (OEM) extends far beyond that of a mere supplier. When it comes to stainless flex tubing, businesses are searching for partners who not only provide high-quality products but also offer comprehensive support and innovative solutions tailored to their unique needs. This is where the distinction of being a trusted partner comes into play, emphasizing a collaborative approach that fosters long-term relationships. A reliable OEM in the stainless flex tubing industry understands the complexities and demands of global procurement. They leverage their extensive experience and technical expertise to ensure that their clients receive products that meet the highest standards of durability and performance. This partnership goes beyond transactional interactions; it encompasses a commitment to understanding clients' operational challenges and delivering customized solutions that enhance efficiency and effectiveness. From ideation to delivery, a trustworthy partner actively engages with clients, ensuring transparency and responsiveness throughout the supply chain. Investing in a partnership with a dedicated OEM can lead to significant advantages, such as enhanced product innovation, improved supply chain efficiency, and cost savings. By fostering a deep understanding of clients' specific goals and challenges, a true partner can contribute to sustainable growth and success in an increasingly competitive market. Embracing this partnership model is not only essential for procurement but also vital for navigating the future of manufacturing together.

Stainless Flex Tubing: Your Trusted OEM Partner More Than a Supplier - A Partner

| Dimension | Material Grade | Application | Connector Type | Custom Options |

|---|---|---|---|---|

| 1" ID x 1.5" OD | 304 Stainless Steel | Automotive Exhaust | Flanged | Custom Lengths |

| 2" ID x 2.5" OD | 316 Stainless Steel | Food Processing | Welded | Branded Labels |

| 3" ID x 3.5" OD | 304L Stainless Steel | Chemical Transfer | Screw-On | Corrosion Resistance |

| 4" ID x 4.5" OD | 316L Stainless Steel | Marine Applications | Clamp | Flexibility Options |

Related Products