Stainless Steel Tubing: Leading Manufacturer in China for Quality Solutions

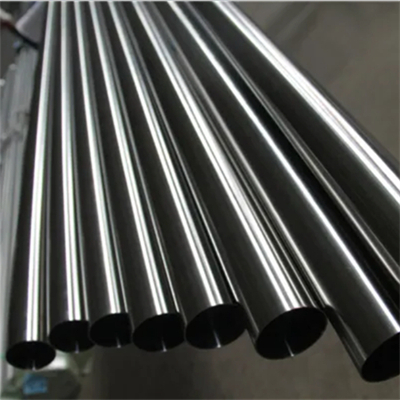

When it comes to high-quality stainless steel tubing, I know the importance of reliability and durability in your projects. Sourced from trusted manufacturers in China, our stainless steel tubing offers exceptional resistance to corrosion and is ideal for a variety of applications, from industrial to residential uses. I find that our tubing not only meets rigorous industry standards but also provides seamless integration with existing systems, making it a smart investment for any purchase. The versatile sizes and customizable options we provide cater to specific buyer needs, ensuring you get exactly what you’re looking for. Whether you are in construction, automotive, or any other sector, our stainless steel tubing is designed to enhance performance and longevity. Let’s work together to find the perfect solution that fits your business needs.

Stainless Steel Tubing Dominates Pioneers in the Field

In recent years, the demand for stainless steel tubing has surged, propelled by its versatile applications across various industries. As global industries strive for efficiency and durability, stainless steel tubing has emerged as a superior choice due to its corrosion resistance, strength, and aesthetic appeal. These properties make it ideal for use in sectors such as construction, automotive, aerospace, and medical equipment, where reliability is paramount. Innovative manufacturing techniques and stringent quality controls have paved the way for the development of high-performance stainless steel tubing that meets the evolving needs of businesses worldwide. As pioneers in the field, companies are focused on not only producing standard sizes but also custom solutions that cater to specific project requirements. This adaptability is crucial in a rapidly changing market where clients demand tailored solutions for unique applications. By investing in cutting-edge technology and sustainable practices, today's leading manufacturers are setting new standards in stainless steel tubing production. As a result, global buyers can expect products that not only offer exceptional performance but also align with environmental regulations and sustainability goals. For procurement professionals, partnering with forward-thinking manufacturers guarantees access to innovative solutions that enhance operational efficiencies and drive long-term success.

Stainless Steel Tubing Dominates Pioneers in the Field

| Pioneer | Specialization | Applications | Material Grade | Innovation Year |

|---|---|---|---|---|

| Pioneer A | Automotive Components | Exhaust Systems | 304 Stainless Steel | 2018 |

| Pioneer B | Medical Devices | Surgical Instruments | 316L Stainless Steel | 2020 |

| Pioneer C | Aerospace Engineering | Airframe Structures | 321 Stainless Steel | 2019 |

| Pioneer D | Oil and Gas | Pipe Systems | duplex Stainless Steel | 2021 |

| Pioneer E | Construction | Structural Tubes | 430 Stainless Steel | 2022 |

Related Products